KIIS Series Three-Phase Gear Motors for Inverters

KIIS Series Three-Phase Gear Motors for Inverters

Oriental Motor, which has set the standard for AC motors, listened and has sought out the next generation in AC motors with the KIIS Series Three-Phase AC gear motors.

The Three-Phase KIIS Series offers an optimally designed, high efficiency next generation three-phase gear motor that incorporates higher strength gears that maximize the motor performance.

- Parallel Shaft or Right-Angle Gear Motors or Round Shaft (no Gear) Models

- Imperial or Metric Shaft options

- Lead Wire or Terminal Box types

- Three-Phase 220/230, 380/415 VAC

AC Gear Motor Lineup

Output Power |

Type |

Gear Type |

Output Shaft |

Options |

Power Supply |

Permissible Torque* |

|

Lead Wire |

Parallel Shaft |

3/4 in. or |

Electromagnetic |

Three-Phase |

23 ~ 350 lb-in |

2.6 ~ 40 N·m |

|

Round Shaft |

12 mm |

80 ~ 97 oz-in |

0.57 ~ 0.69 N·m |

||||

Lead Wire |

Right-Angle Hollow Shaft Gear |

15 mm |

- |

Three-Phase |

36 ~ 470 lb-in |

4.1 ~ 53.9 N·m |

|

Right-Angle Solid Shaft Gear |

18 mm |

36 ~ 470 lb-in |

4.1 ~ 53.9 N·m |

||||

Terminal Box |

Right-Angle Hollow Shaft Gear |

15 mm |

- |

Three-Phase |

36 ~ 470 lb-in |

4.1 ~ 53.9 N·m |

|

Terminal Box |

Parallel Shaft |

22 mm |

- |

Three-Phase Three-Phase |

53 ~ 610 lb-in |

5.1 ~ 70 N·m |

|

Round Shaft |

14 mm |

160 ~ 191 oz-in |

1.13 ~ 1.35 N·m |

||||

Right-Angle Hollow Shaft Gear |

25 mm |

36 ~ 530 oz-in |

4.1 ~ 60 N·m |

||||

*Torque and Speed vary based on input voltage and frequency, please review product specifications for details.

High Performance AC Gear Motors

- 100 W (1/8 HP)

- 200 W (1/4 HP)

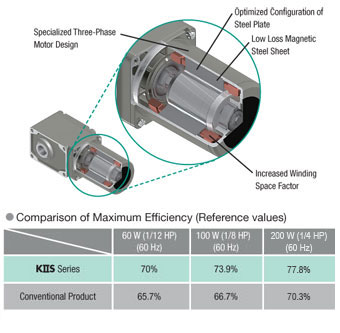

High Efficiency at a Maximum of 77.8%*

Specialized components and optimal magnetic design are used to make high efficiency three-phase motors with a maximum efficiency of 77.8%*. Motors are fanless, with increased motor output and significant loss reduction.

*200 W (1/4 HP) KIIS Series meets IE4 Standards.

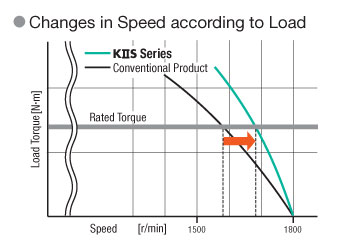

High Performance

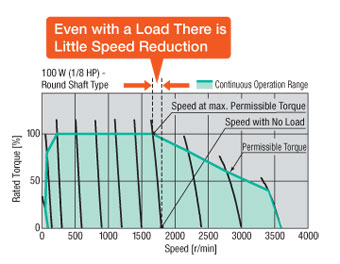

Characteristics have been improved through pursuit of the specifications required for the three-phase motor and a review of the design to create a high-performance motor with little speed reduction even with a large load.

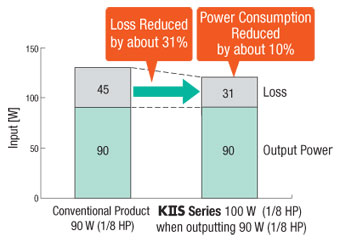

Power Consumption Reduced by up to 10%

Compared to a conventional 90W product under the same conditions, power consumption is reduced by a maximum of about 10%, contributing to the the equipment's energy savings.

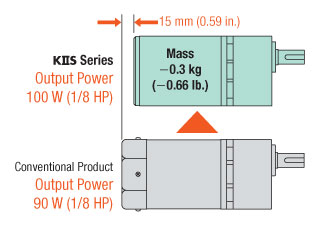

Increased Motor Output

Output power of 100 W (1/8 HP) in a 90 mm (3.54 in.) frame size is achieved through increased efficiency. An overall length 15mm (0.59 in.) shorter than the conventional product contributes to equipment downsizing.

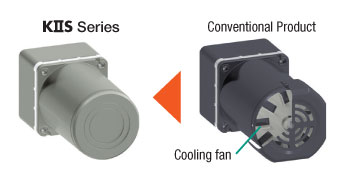

Fanless

With reduced loss, there is less heat generation in the motor, so the cooling fan is no longer needed. With no cooling fan, dust is not blown around.

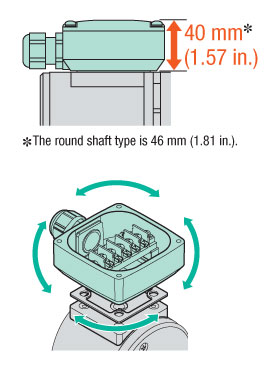

Equipped with an Easy-to-Wire, Slim Body Terminal Box

This new shape of terminal box is designed to make wiring the terminal block easier. It has a slim body, with a cable outlet that can be rotated in 90° increments for 4 possible directions.

IP66-Compliant Drip-Proof Specification

The seal structure for the motor, gearhead and terminal box components has been strengthened. The terminal box type* is compliant with the IP66 degree of protection.

*Excluding installation surface of the round shaft type.

IP66:

The IP indication that shows the watertight and dust-resistant performance are specified under IEC 60529 and IEC 60034-5.

Main Specifications:

- Material

Case and terminal box: Aluminum

Output shaft: S45C

Screws: Stainless steel (externally facing screws only) - Surface Treatment

Case and terminal box: Painted (excluding installation surface)

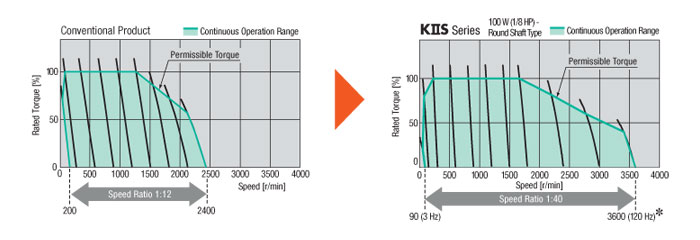

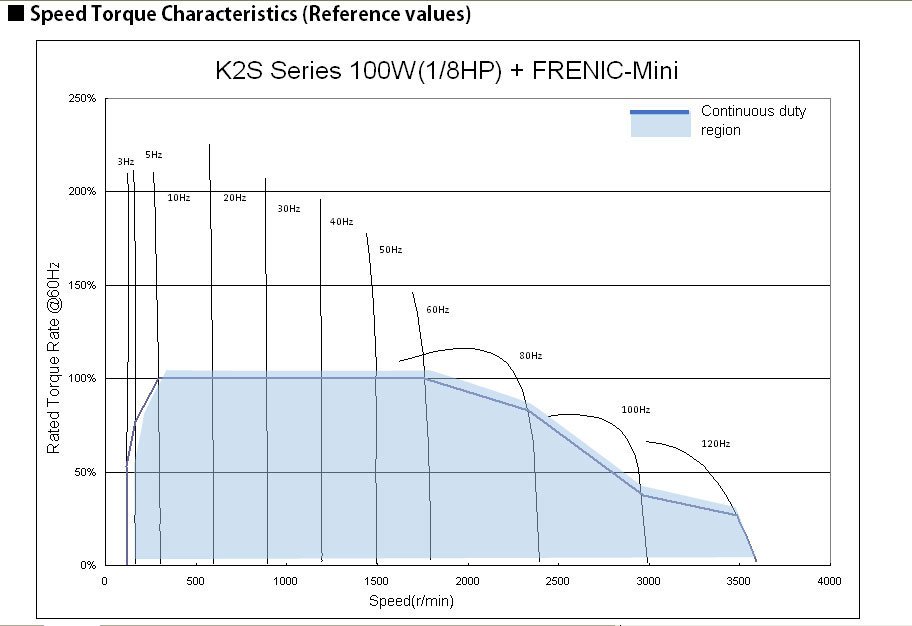

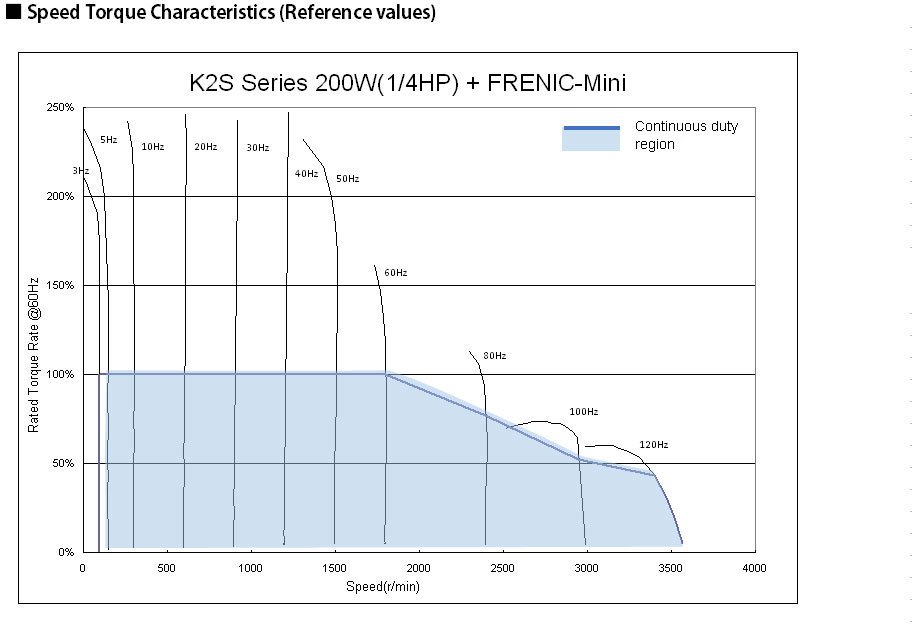

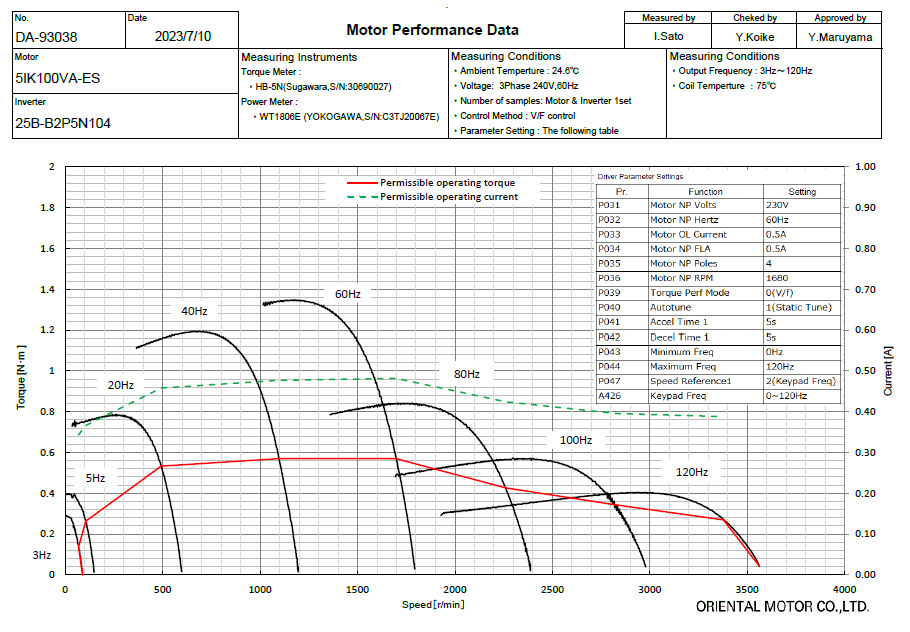

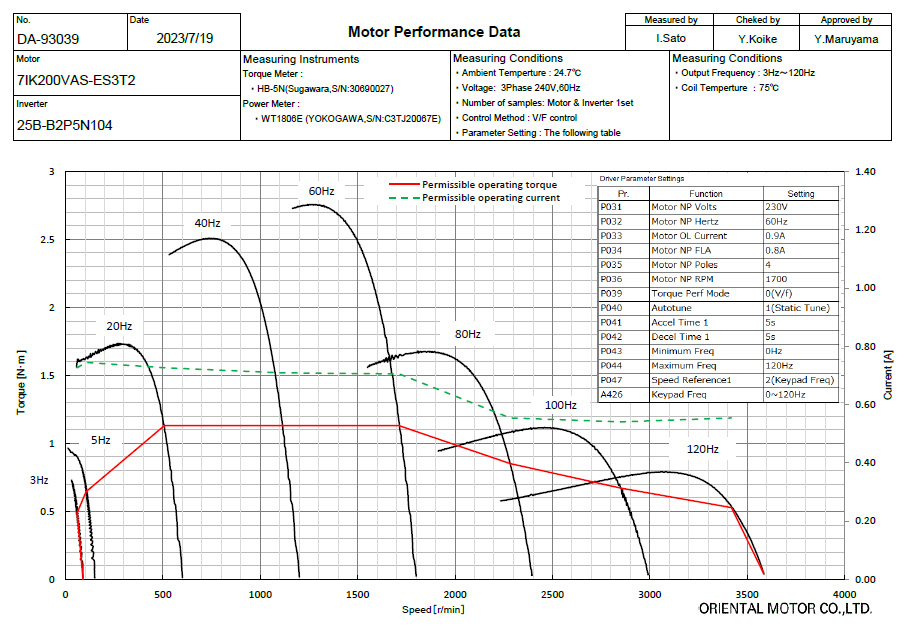

Best Characteristics Achieved when Combined with Inverter

Wide Range of Speeds

Speed can be controlled over a wide range using an inverter, from 3~120 Hz*. Also, with improved characteristics, high torque can be exerted even at low speeds.

Improved Speed Stability

Because it is a high-performance motor with little speed reduction even with a large load, stabilized speed control is possible.

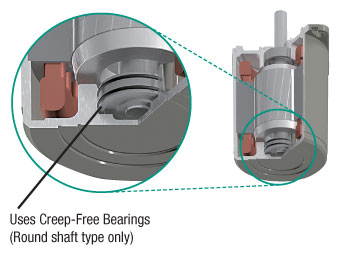

Handles High-Speed Rotation (Round shaft type)

Creep-free bearings, etc. are used in the round shaft type and components capable of handling high-speed rotation have been selected and designed for inverter control.

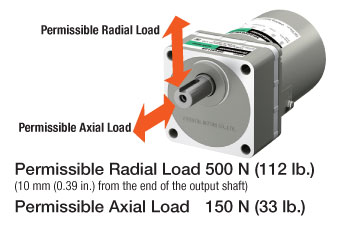

Parallel Shaft Type

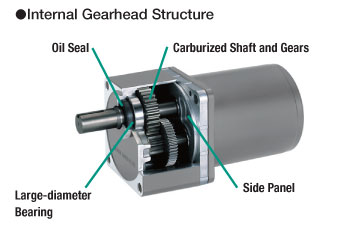

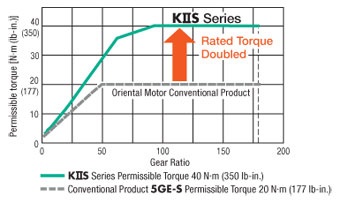

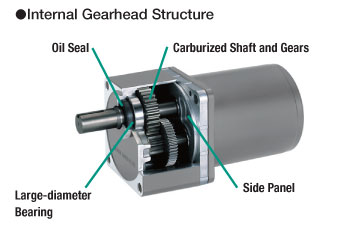

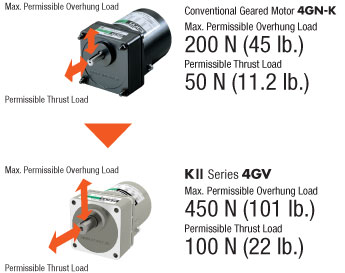

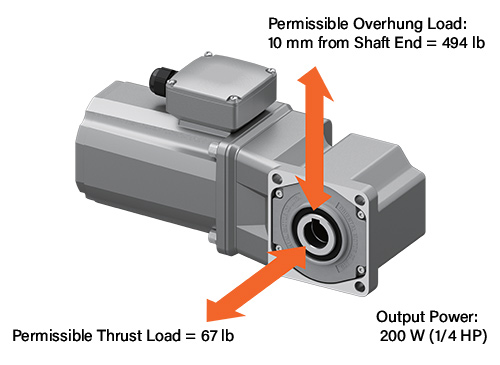

High Strength

Permissible overhung load and permissible thrust load have doubled compared to conventional products*. This has been made possible by increasing the case rigidity, adding larger diameter bearings and improved gear strength through heat treatment.

*The same in some products.

Permissible overhung load and permissible thrust load have doubled compared to conventional products. (40 W vs. 25 W comparison).

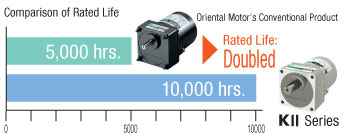

Long Life

The gearhead ball bearing diameter has increased, resulting in doubling the life of the gearhead (10,000 hours compared to the rated life of 5,000 hours for conventional gearheads). Performing maintenance has decreased as a result of the longer life.

The rated life has doubled compared to conventional products.

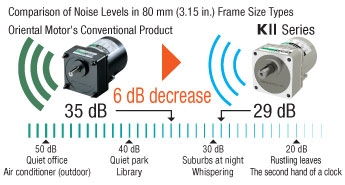

Quiet

The motor and gearhead noise (meshing sound) has decreased by approximately 6 dB compared to conventional motors. Put into perspective, the noise level has decreased by 50%.

The gearhead noise has been decreased by 6 dB compared to conventional products.

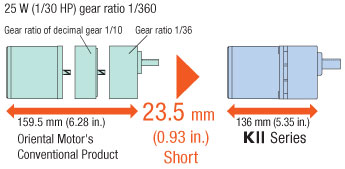

High Gear Ratio

Decimal gearheads were once required for gear ratios above 1:180. Now a single gearhead is available (up to 1:360), saving space and reducing components and costs.

No decimal gearhead is required, allowing the total length to be shortened.

Tap Output Shaft

An end tap has been integrated into the tip of the output shaft of gearheads, with a rated output power of 25 W (1/30 HP) and higher. The tap can be used to prevent pulleys and other transmission mechanisms from slipping.

IP66 Stainless Steel Shaft Type

- 100 W (1/8 HP)

Motors with terminal box conforming to IP66 rating for degree of protection.

Right-Angle Hypoid Gearhead

- 100 W (1/8 HP)

- 200 W (1/4 HP)

Motors with terminal box conforming to IP66 rating for degree of protection.

Right-Angle Hollow Shaft JH Gear

The Right-Angle Hypoid Gearhead uses an output shaft made of stainless steel, which has excellent rust and corrosion resistance.

Right-Angle Hollow Shaft GV Gear

The right-angle gearhead adopts a hypoid gear, and a high-strength gear is arranged to increase the strength.

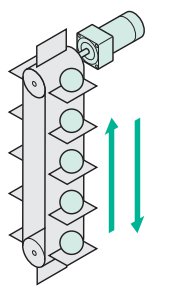

Electromagnetic Brake Type

- 100 W (1/8 HP)

These motors have a "power off" activated type electromagnetic brake to hold the load in position when the power is cut off.

Ideal for Applications Required Load Holding

This configuration is ideal for vertical applications where the load must be held.

Performance Examples with Fuji Mini

100 W (1/8 HP)

200 W (1/4 HP)

Performance Examples with Rockwell PowerFlex

100 W (1/8 HP)

200 W (1/4 HP)

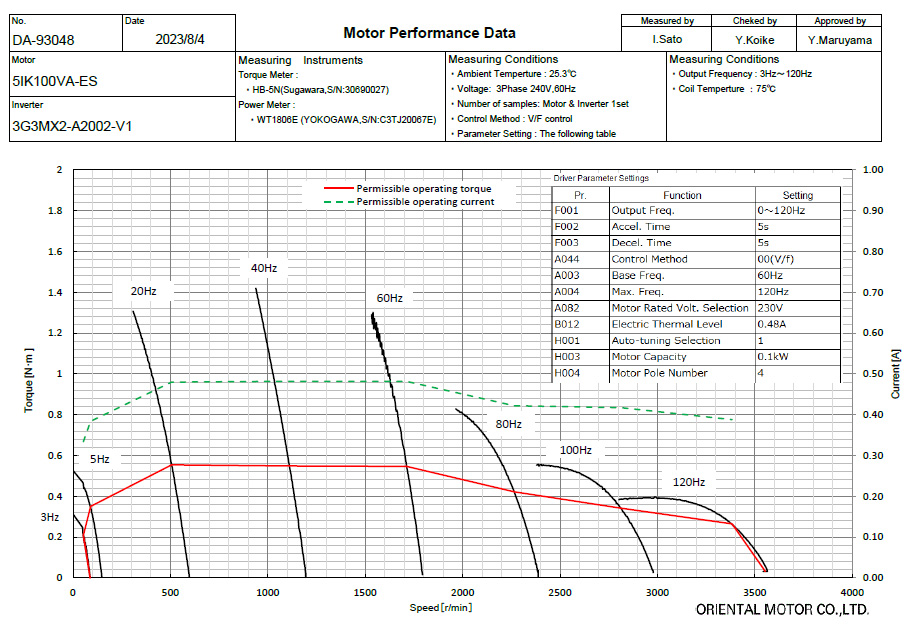

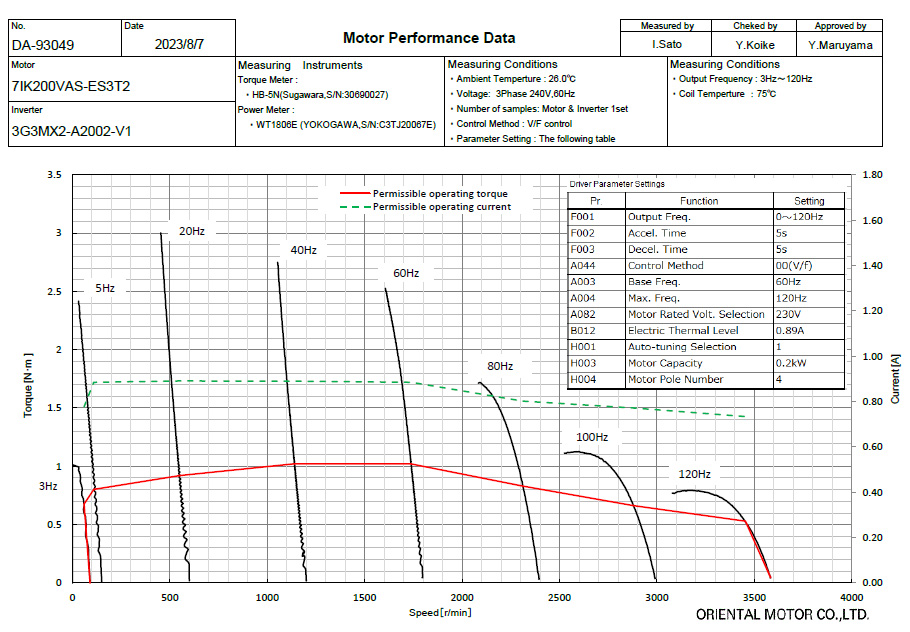

Performance Examples with Omron MX2

100 W (1/8 HP)

200 W (1/4 HP)

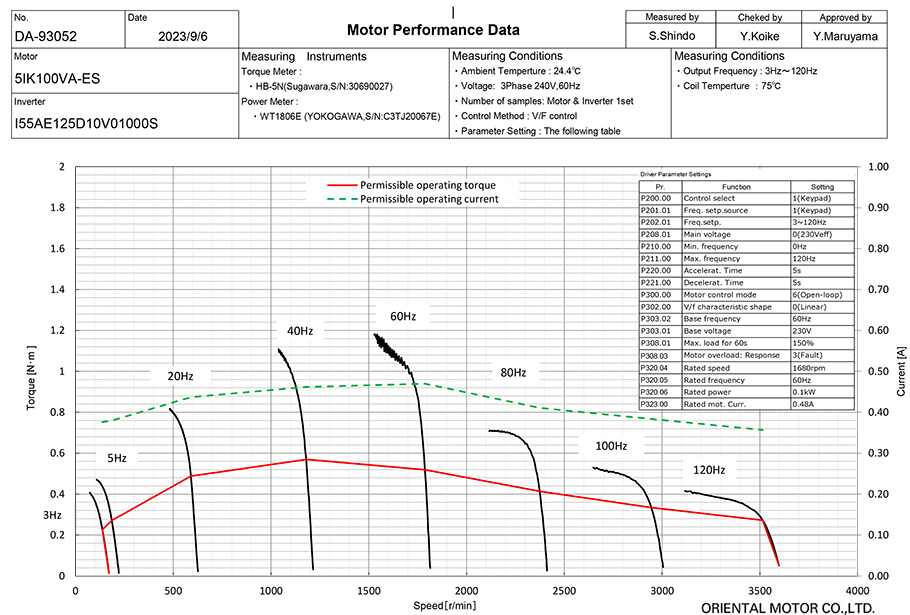

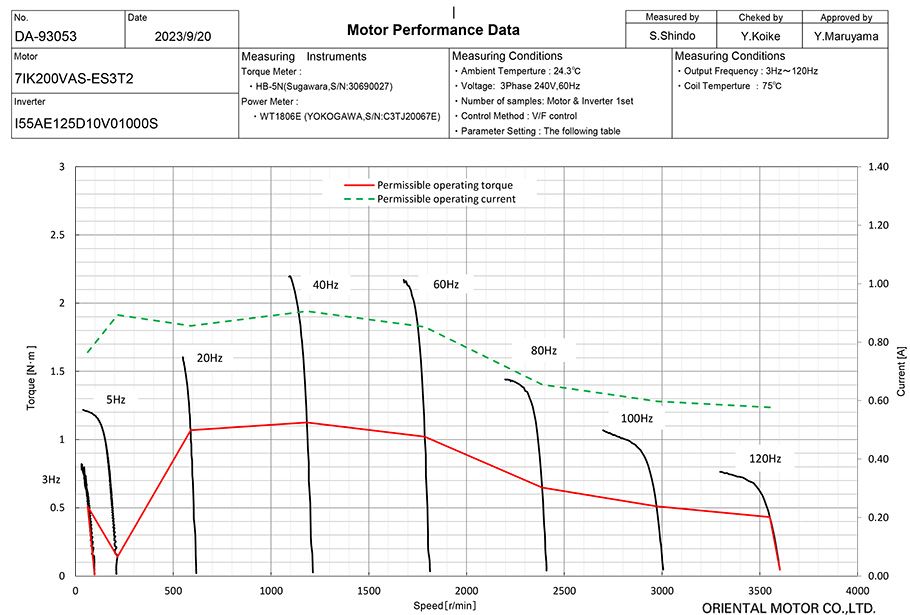

Performance Examples with Lenze

100 W (1/8 HP)

200 W (1/4 HP)

Inverter / VFD

With its high functionality, compact design, simple operation and global compatibility, the new FRENIC-Mini (C2) elevates the performance of a wide range of devices and equipment--including conveyors, fans, pumps, centrifugal separators, and food processing machines--to give you the system integration, energy efficiency, reduced labor, and lower overall costs you're looking for.

- Single-Phase 115 VAC or 230 VAC input, Three-Phase 230 VAC or Three-Phase 460 VAC input.

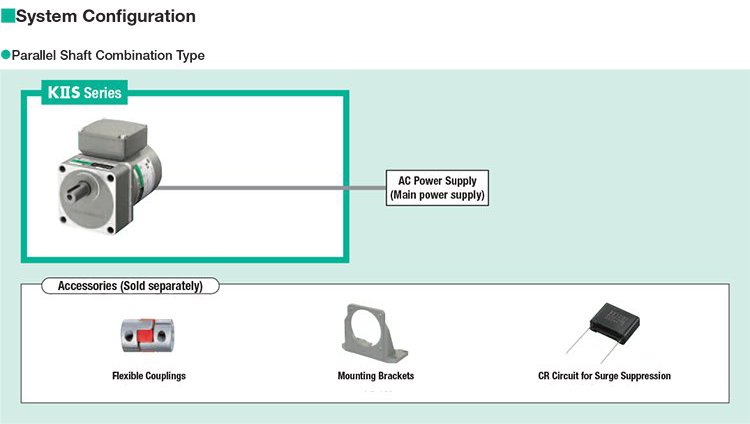

CR Circuit for Surge Suppression

This product is used to protect the contacts of a relay or switch used in the forward/reverse circuit section or the instantaneous stop circuit section of a motor.

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

Mounting Bracket

This is an aluminum die cast mounting bracket for geared motors.

Long, horizontal holes make it easy to make fine adjustments during installation.

Torque Arm

A torque arm acts as an anti-spin mechanism when a right-angle shaft, hollow hypoid JH gear is installed to prevent gearheads from rotating due to reactive force from shafts being driven.

Output Power |

Item |

100 W (1/8 HP) |

|

200 W (1/4 HP) |

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.