BLH Series Brushless DC Motors (DC Input)

BLH Series Brushless DC Motors (BLDC Motors) - DC Input

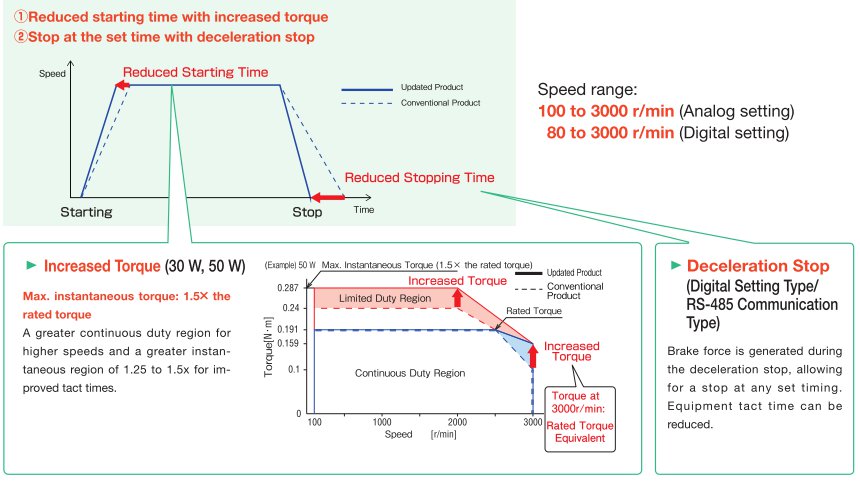

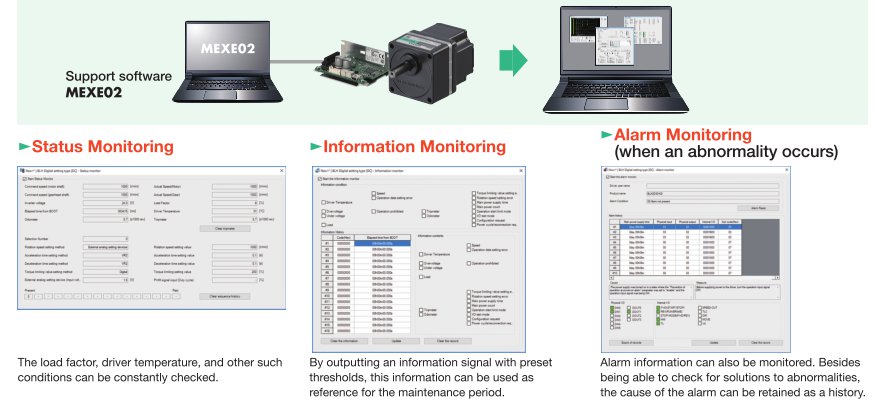

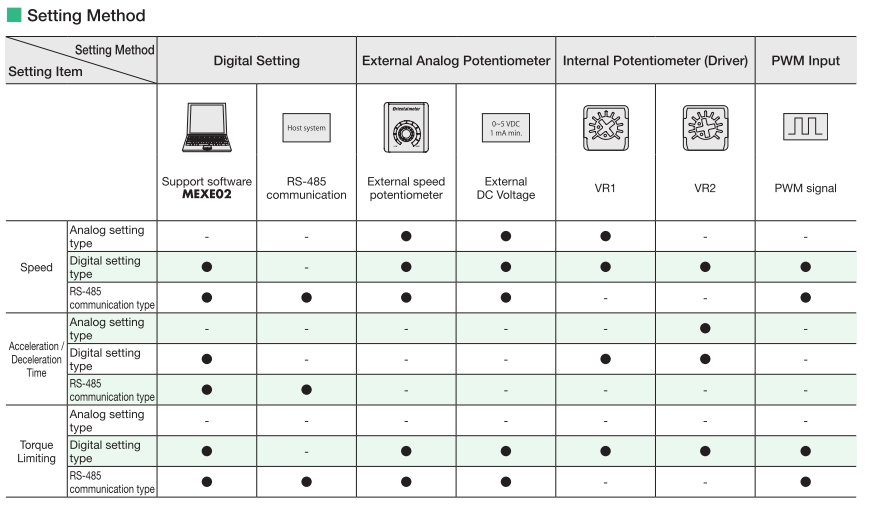

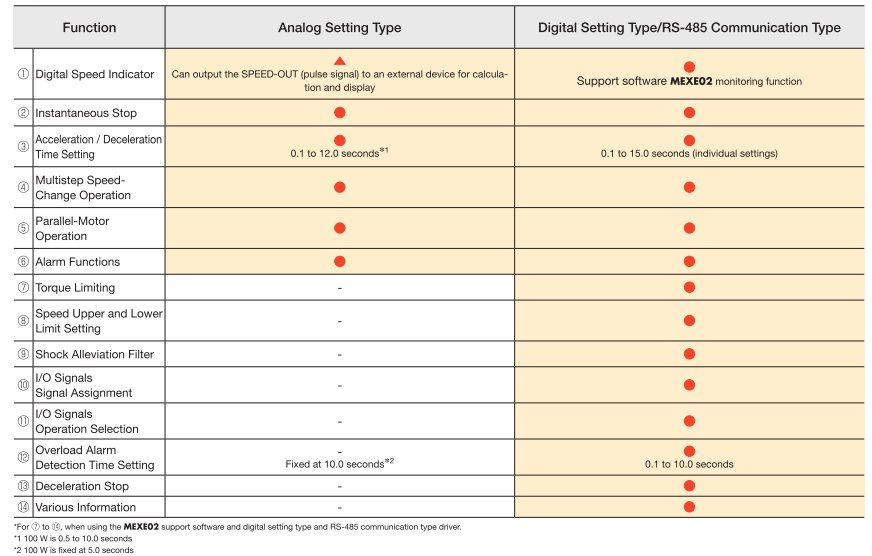

The BLH Series Driver has been updated to now include three driver types; RS-485 Communications type, a Digital type driver or the traditional Analog type. The BLH Series is a 24 VDC, brushless DC motor and driver package offering a wide speed range of 100 to 3000 r/min (80 to 3000 r/min with digital driver type and RS-485 communication type). RS-485 Communication and Digital type driver is used with our MEXE02 support software (available for free download) for improved functions including torque sensing and predictive maintenance monitoring. A wide range of motor options are available to meet you application needs.

The BLH Series comes with long-life, high-strength gearheads that can produce up to 600 lb-in of torque.

- Compact, Board-type Driver (Analog, RS-485 Communication or Digital type)

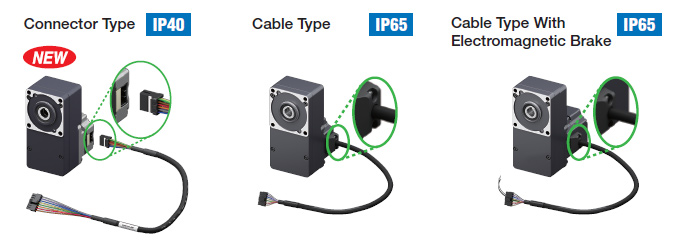

- Cable or Connector Type Motors

- Speed Control via Potentiometer, DC Voltage or Support Software (Digital type)

- Torque Sensing and Monitoring (RS-485 or Digital type)

- 24 VDC

- Parallel Shaft, Hollow Shaft Flat Gear or Round Shaft (no Gear)

- Electromagnetic Brake Available

Brushless DC Motor (BLDC Motor) & Gear Motor Lineup

Output Power |

Gear Options |

Options |

Power Supply |

Rated Torque |

Speed Range |

|

Parallel Shaft |

- |

24 VDC |

1.94 ~ 17.7 lb-in |

0.22 ~ 2 N·m |

100 ~ 3000 r/min Min: 0.5 [200:1] |

|

Round Shaft (no Gear) |

6.8 oz-in |

0.048 N·m |

||||

Parallel Shaft |

Electromagnetic Brake |

24 VDC |

4.6 ~ 53 lb-in |

0.52 ~ 6 N·m |

100 ~ 3000 r/min Min: 0.5 [200:1] |

|

Hollow Shaft Flat |

4.0 ~ 150 lb-in |

0.46 ~ 17 N·m |

||||

Round Shaft (no Gear) |

16.3 oz-in |

0.115 N·m |

||||

Parallel Shaft |

Electromagnetic Brake |

24 VDC |

7.6 ~ 141 lb-in |

0.86 ~ 16 N·m |

100 ~ 3000 r/min Min: 0.5 [200:1] |

|

Hollow Shaft Flat |

7.1 ~ 300 lb-in |

0.81 ~ 34 N·m |

||||

Round Shaft (no Gear) |

27 oz-in |

0.191 N·m |

||||

Parallel Shaft |

Electromagnetic Brake |

24 VDC |

15.9 ~ 260 lb-in |

1.8 ~ 30 N·m |

100 ~ 3000 r/min Min: 0.5 [200:1] |

|

Hollow Shaft Flat |

15 ~ 600 lb-in |

1.7 ~ 68 N·m |

||||

Round Shaft (no Gear) |

56 oz-in |

0.4 N·m |

||||

*100W only available with Analog Driver type.

Brushless DC Motors (BLDC Motors)

Brushless DC motors have slim bodies and provide high output and high efficiency due to the built-in permanent magnets. The built-in sensor (hall IC) constantly monitors the motor's speed. No matter the load conditions, feedback control is carried out at all times so that the command speed and actual speed remain constant.

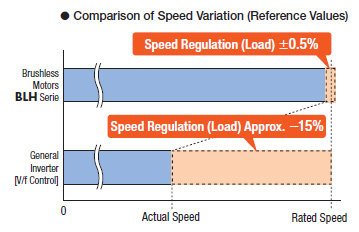

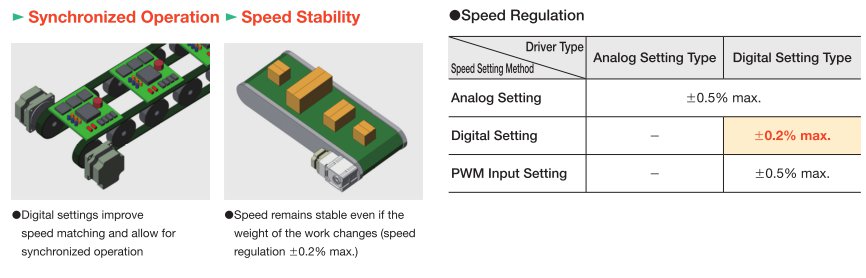

Speed stability with feedback control

Brushless DC motors compare the setting speed with the speed feedback signals from the motor at all times and adjust the motor's applied voltage. Speed is kept stable over the entire speed range from low to high even when the load fluctuates.

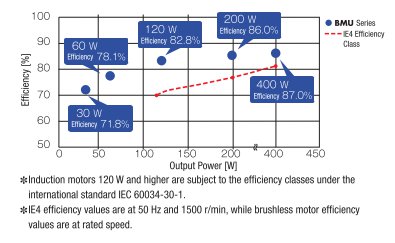

IE4-equivalent* high-efficiency and energy-saving motor

Brushless DC motors are higher efficiency than three-phase motors (induction motors).

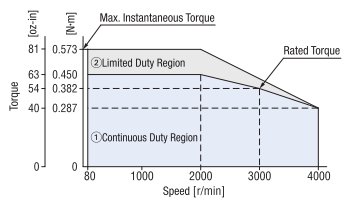

Broad speed control range and flat torque

Rated torque is consistent over the entire speed range from low to high. Sufficient torque is obtained without limiting the used torque at low speeds, as is done with three-phase motors when driven with an inverter.

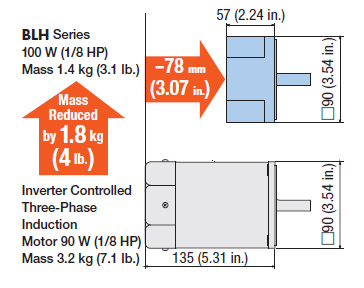

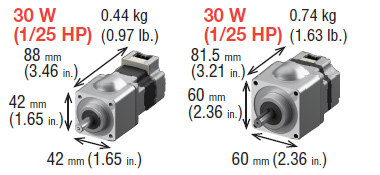

Compact, lightweight and high power

Since these are brushless DC motors with built-in permanent magnets, they offer high output even though they are compact. Installation is easy and both equipment weight and space can be reduced.

Motor Types

Types to suit a variety of environments are available, including the connector type with selectable cable length and motors conforming to IP65 rating for degree of protection. For applications in which holding is required during horizontal operation, Oriental Motor offers motors with an electromagnetic brake.

NEW! Connector Type

Direct connection to driver. No extension required.

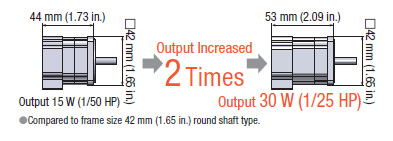

Next-level output has been achieved by increasing the thickness of the motor's steel plates without changing its frame size. Meets customers’ needs for higher output without changing the installation design.

The size and weight of the equipment can be reduced without changing its power.

3 Types of Drivers to Choose From

Analog Setting Type

- Installation and functional compatibility with current products

- Increased Performance (higher torque, reduced audible noise)

- 15 W, 30 W, 50 W and 100 W

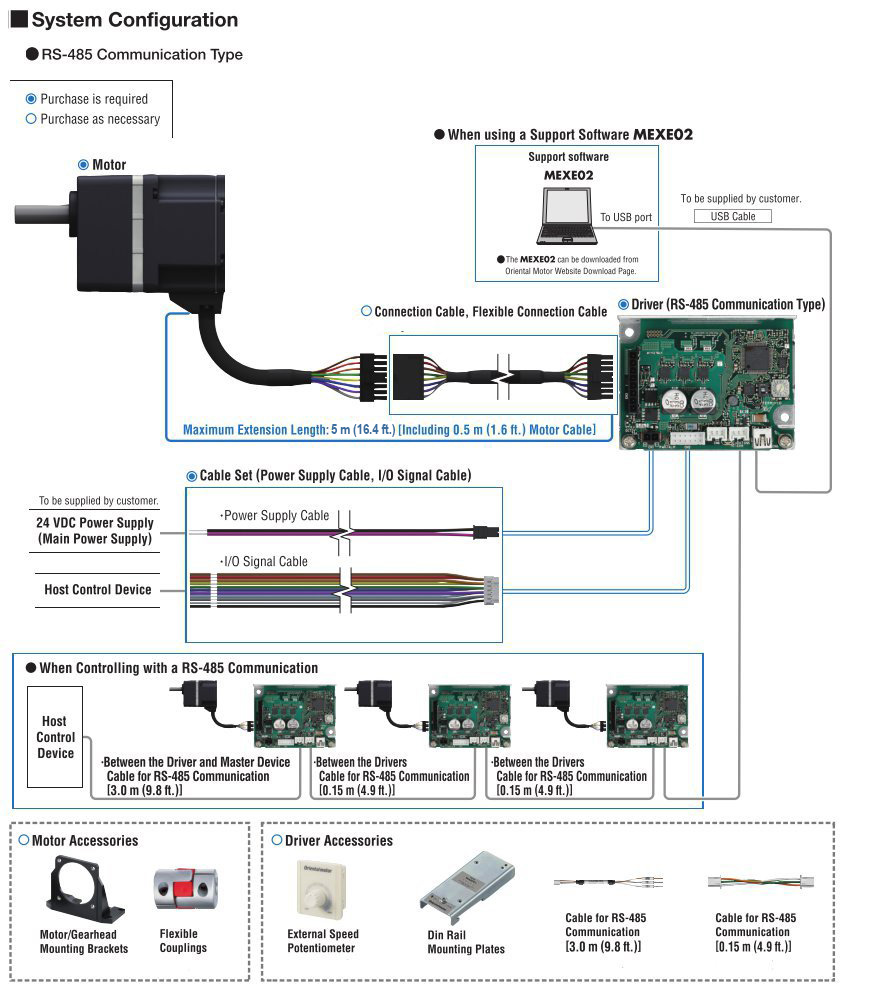

RS-485 Communications Type

- Installation compatibility with current products

- Increased Performance (higher torque, reduced audible noise)

- Increased functionality with Support Software (MEXE02)

- 15 W, 30 W and 50 W

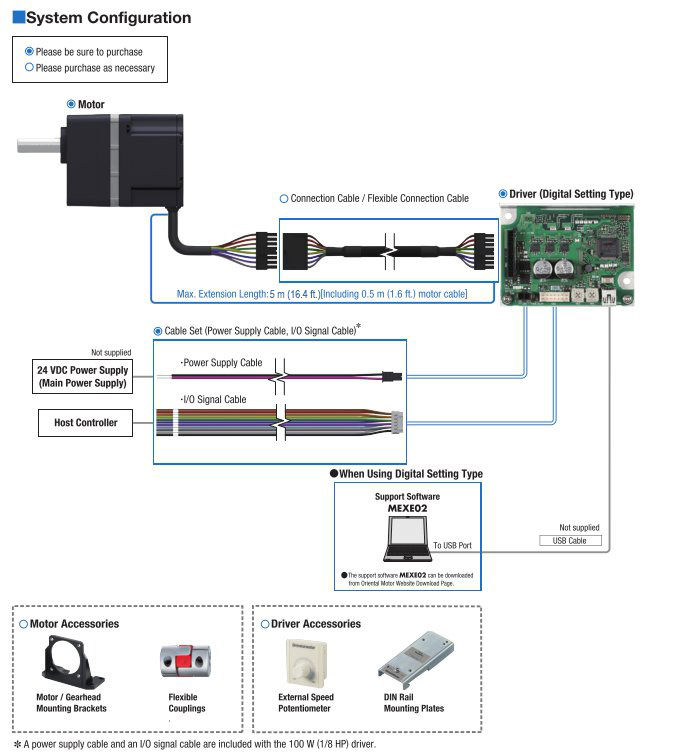

Digital Setting Type

- Installation compatibility with current products

- Increased Performance (higher torque, reduced audible noise)

- Increased functionality with Support Software (MEXE02)

- 15 W, 30 W and 50 W

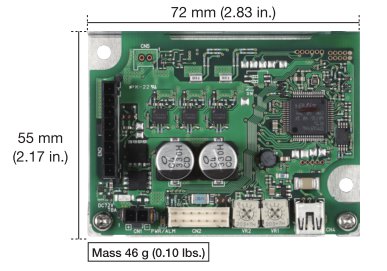

Compact Board-Type Driver

Compact, lightweight drivers that are smaller than a business card.

Full Range of Driver Functions

The compact driver is packed with a full range of functions.

- Instantaneous stop

- Speed control via potentiometer

- Speed control by DC voltage

- Speed control by MEXE02 support software (RS-485 or Digital type)

- Acceleration/deceleration time setting

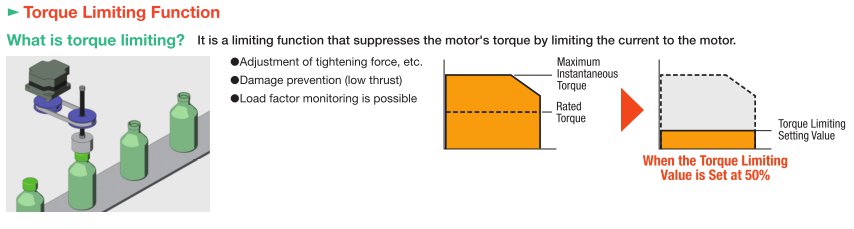

- Torque Limiting Function (RS-485 or Digital type)

- Alarm output

Increase Performance and Value with New Drivers

Reduction in Equipment Tact Time

Suitable for Applications in Quiet Environments

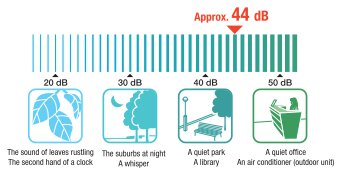

Noise Value approx. 44 dB (reduced by approx. 13 dB)

Noise sounds about half as loud as conventional products.

*30W with parallel shaft gearhead (5:1)

*Measurement of noise: OA value

The BLH Series uses a sinusoidal drive method. With little torque ripple and smooth, stable rotation even at low speeds, the motor's drive sound is reduced.

Synchronized Operation and Operation with Little Speed Fluctuation

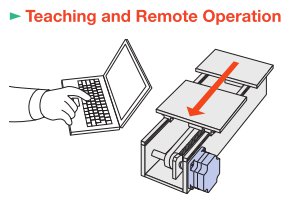

Startup and Maintenance with Digital Settings + Support Software

Equipment Startup Assistance

Operating data can be set on the computer screen. It is possible to perform a test run without connecting the host system, then record the operating data as-is.

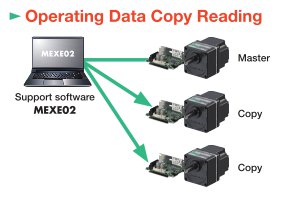

Copy the operating data to the driver when using multiple units and read out the data on the driver side. This contributes to reduced system startup time.

Predictive Maintenance with Visualization

What is predictive maintenance? By constantly monitoring the status of the motor and performing maintenance when signs of change are observed, trouble can be avoided.

Torque Adjustment

Besides applications such as adjustment of tightening force, it can also be used as a safety measure for pinching detection and equipment damage prevention. he max. instantaneous torque range can be set between 0 and 200% by assuming the rated torque to be 100%.

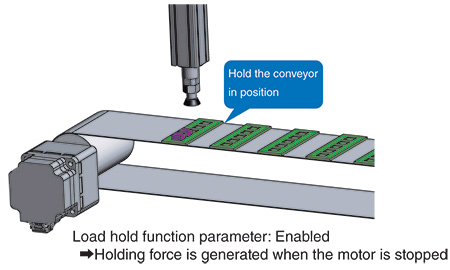

Load Holding Function (RS-485 or Digital Type)

The load holding function can be used to electrically hold* the load in place without an electromagnetic brake. For example, work can be performed on the load when it's held in place on a conveyor.

*It can hold a load with a rated torque of up to 50%.

Note: When the power supply to the driver is turned off, the holding torque is lost. It cannot be used to prevent falling when stopped.

No need for a maintenance

It is also suitable for applications where the load needs to be stopped frequently. Since there are no mechanical parts, it contributes to a longer life.

Space saving of equipment

Since no mechanical brake is required, it contributes to space saving and weight reduction in the device.

Operating Data Setting

When using the digital setting type, operating data for up to 8 points can be set.

Functions

Long-Life, Parallel Shaft Gearhead

- 15 W (1/50 HP)

- 30 W (1/25 HP)

- 50 W (1/15 HP)

- 100 W (1/8 HP)

The high-strength gearhead is designed to withstand high-speed revolutions. The rated life of the gearhead is 10000 hours*, which is twice as long as that of our previous gearhead.

*5000 hours for gearhead equipped with 15 W (1/50 HP) brushless DC motor.

Up to 260 lb-in of Torque Possible

[100 W (1/8 HP) Brushless DC Motor with Parallel Shaft Gearhead]

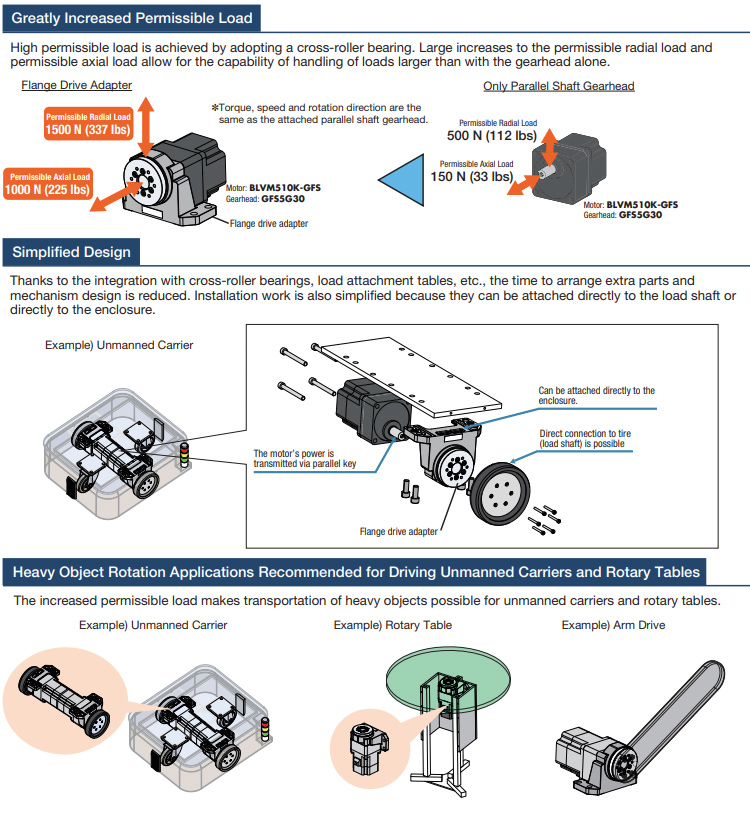

Flange Drive Adapter available for 100 W (1/8 HP) Parallel Shaft Gear Motors

Permissible load has been increased by mounting with a parallel shaft gearhead. Direct mounting of the rotation mechanism to wheels or rotary tables has been simplified, which helps reduce design time.

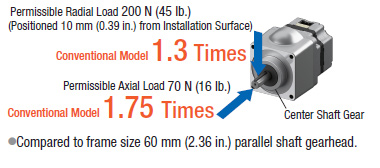

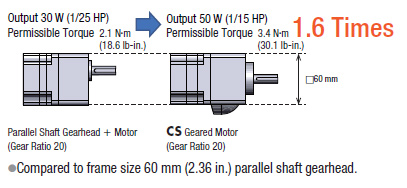

CS (Center Shaft) Gearhead

- 30 W (1/25 HP)

- 50 W (1/15 HP)

Reduced Equipment Size and Increased Load-Bearing Capacity

With characteristics such as “increased load-bearing capacity/next-level torque/center shaft”, the CS Geared Type not only makes equipment faster and more compact but also contributes to improved freedom of design for customers.

Increased Load-Bearing Capacity Compared with Parallel Shaft Gearhead

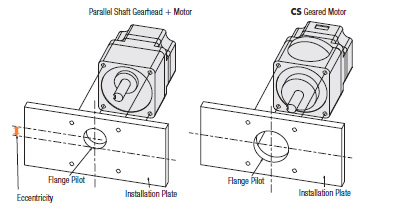

Achieves Next-Level Torque with Same Frame Size

Simplified Design

With no eccentricity, CS geared motors contribute to the simplicity of equipment design.

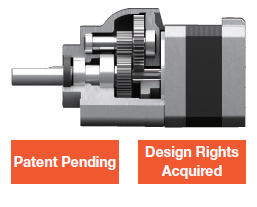

Structure of Center Shaft Gear

The center shaft gearhead has been achieved by positioning the large gear so that it is free of the central axis.

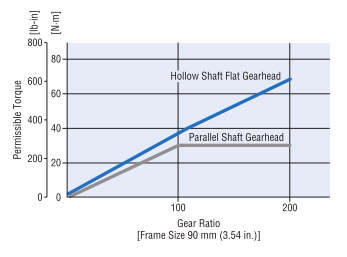

Hollow Shaft Flat Gearhead

- 30 W (1/25 HP)

- 50 W (1/15 HP)

- 100 W (1/8 HP)

Permissible Torque without Saturation

The hollow shaft flat gearhead enables permissible torque without saturation even at high gear ratios. The motor torque can be fully utilized.

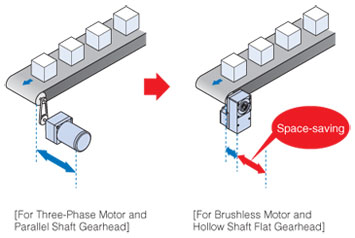

Low Cost

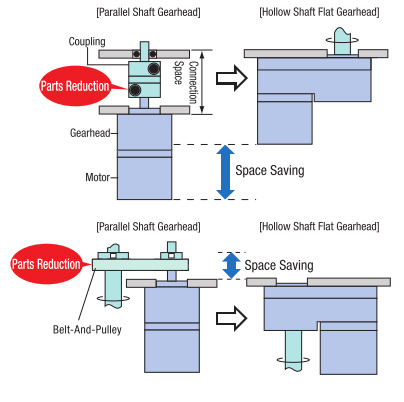

By eliminating parts such as a coupling or belt-and-pulley, the parts cost and labor will also decrease.

Space Saving is Achieved with a Hollow Shaft Flat Gearhead

The output shaft can be coupled directly to your drive shaft without using a coupling. The flexible installation modes, such as installation on either the front or rear face or by using the center shaft, allows you to reduce the size and installation space of your equipment. Since no shaft-coupling parts are needed, the parts cost and assembly man-hours will also decrease.

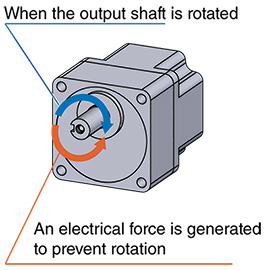

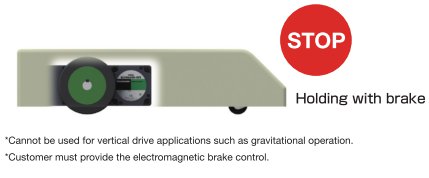

Electromagnetic Brake

- 30 W (1/25 HP)

- 50 W (1/15 HP)

- 100 W (1/8 HP)

Stop and Hold Using Electromagnetic Brake

- The stop position can be maintained when stopping the equipment to load and unlock or process work pieces.

- Hold loads during unexpected occurrences such as power outages.

Confirm motor is stopped by MOVE output

- The electromagnetic brake release timing can be confirmed using the MOVE output for digital setting type and RS-485 communication.

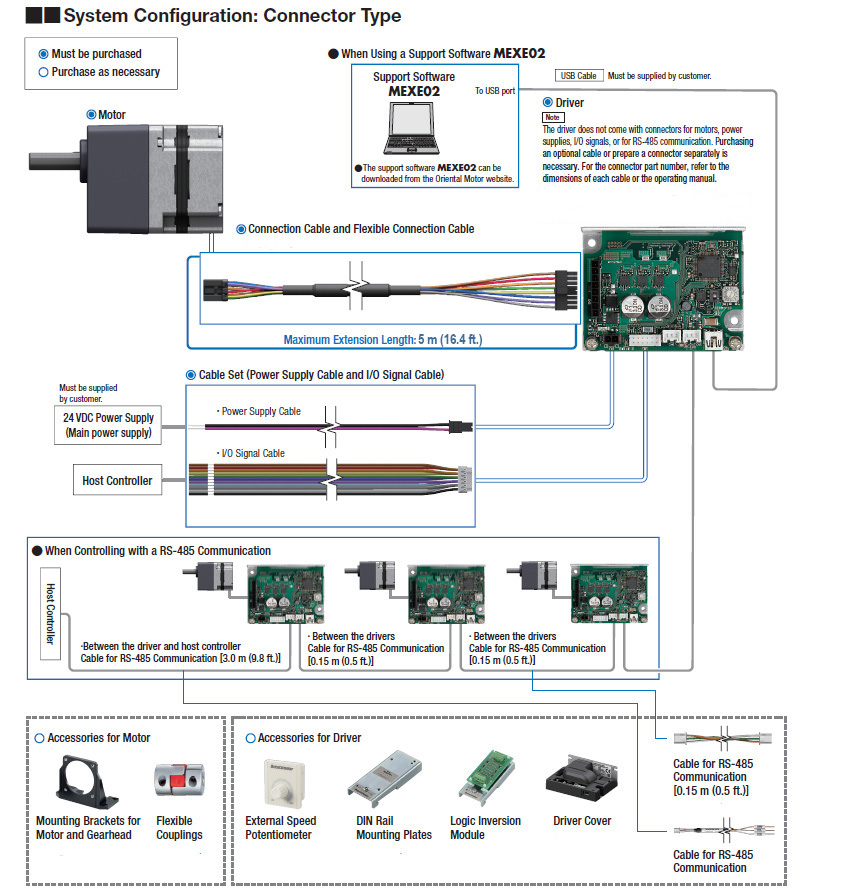

Driver Cable Set*

Power supply cable is used to connect the driver and the power supply. I/O signal cable is used to connect the driver and programmable controller.

*Cables required for 15W, 30W and 50W drivers, included with 100W driver

Analog & RS-485 Driver |

0.3 m |

|

1 m |

||

Digital Driver |

0.3 m |

|

1 m |

RS-485 Communication Cables

Communication cables for RS-485 type drivers.

Driver to Controller |

|

Driver to Driver |

Connection Cables for Connector Type Motors

Single Cable for Connector Type Motors (required)

Extension Cables for Cable Type Motors

These cables extend the distance between the motor and driver.

The motor includes a 20 in. (500 mm) cable.

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

Mounting Bracket

This is an aluminum die cast mounting bracket for geared motors.

Long, horizontal holes make it easy to make fine adjustments during installation.

Flange Drive Adapter

Permissible load has been increased by mounting with a parallel shaft gearhead. Direct mounting of the rotation mechanism to wheels or rotary tables has been simplified, which helps reduce design time.

*For use with 100W Parallel Shaft Gear Motors

External Speed Potentiometer

Sets and adjusts the motor's speed. Package includes one potentiometer.

(20 kΩ, 1/4 W and with a linear resistance vs. angle curve)

Driver Cover

This cover provides protection for the driver and prevents accidental contact.

15W, 30W, 50W |

DIN Rail Mounting Plate

DIN rail mounting bracket for driver

15W, 30W, 50W |

|

100W |

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.