Advanced Technology at Affordable Prices

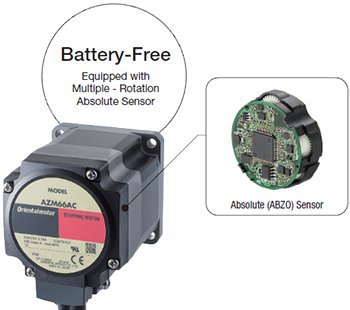

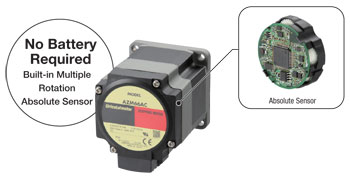

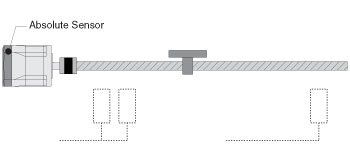

Oriental Motor has developed and patented a compact, low-cost, battery-free mechanical type absolute sensor. The αSTEP AZ Series stepper motor is available at affordable prices and can contribute to improved productivity and cost reductions.

Mechanical-Type Encoder (No Battery Required)

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears. As a result, it does not require a battery.

Multiple-Rotation Absolute System*

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the home position.

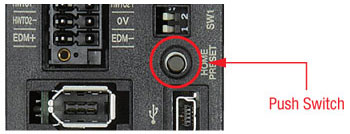

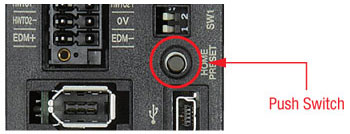

Home Setting Method*

The home position can be easily set by pressing a switch on the drivers surface, which is saved by the Mechanical Absolute Encoder. In addition, home setting is possible with the MEXE02 data setting software or external input signal.

Home position is easy to adjust by moving the motor to a desired position manually.

*Requires AZ Series Driver

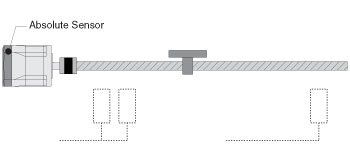

No External Sensors Required

Positional information is managed mechanically. External sensors such as home sensor and the limit sensor are not needed.

Reduced Cost

Sensor costs and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified and the degree of freedom for equipment design is increased.

Not Affected by Sensor Malfunctions

There is no concern about sensor malfunctions (when operating in environments filled with oil mist or filled with metal pieces due to metal processing), sensor failures or sensor wire disconnections.

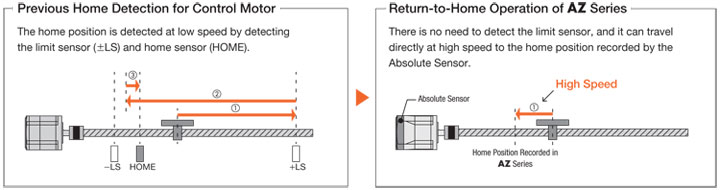

Improved Return-to-Home Accuracy

Home position accuracy is increase because the return-to-home operation is performed regardless of any variations in home sensor sensitivity.

Shortened Reset Time - High Speed Return-to-Home

Because return-to-home is possible without an external sensor, return-to-home can be performed at high speed without taking the sensor sensitivity into account, allowing for a shortened machine cycle.

No Battery Required

No battery is required thanks to a mechanical-type sensor. Because positioning information is managed mechanically by the Mechanical Absolute Encoder, the positioning information can be preserved, even if the power turns off, or the cable between the motor and the driver is disconnected.

Reduced Maintenance

Because there is no battery that needs replacement, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Mechanical Absolute Encoder does not require a battery, so there is no limit to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

Position Holding Even when the Cable between the Motor and Driver is Detached

Positioning information is stored within the Mechanical Absolute Encoder.

*Because the positioning information is stored in the Mechanical Absolute Encoder, the home position must be reset if the motor is replaced.

High Reliability

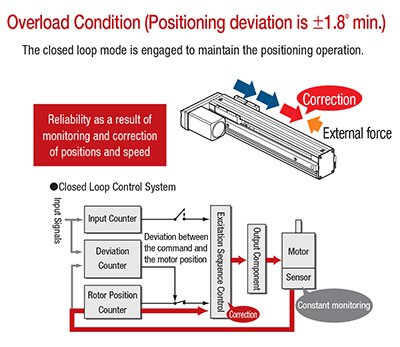

High Reliability is provided by using the control method unique to Oriental Motor that combines the merits of both open loop control and closed loop control.

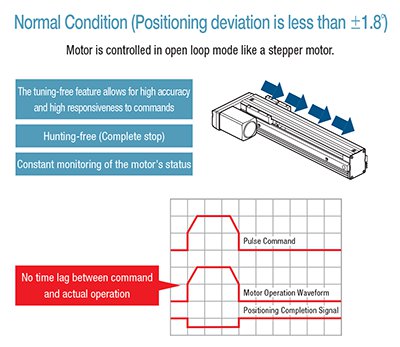

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

In normal conditions, it operates synchronously with pulse commands under open loop control, and because of its compact size and high torque generation, it has excellent acceleration performance and response. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If a continuous overload is applied, an alarm signal is output. Also, when the positioning is completed, a signal is output. This provides high reliability.

No Tuning Required

Because it is normally operated with open loop control, positioning is still possible without gain tuning even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Holding the Stop Position

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

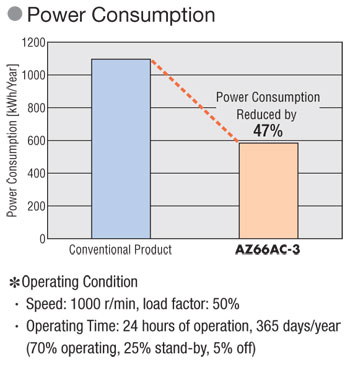

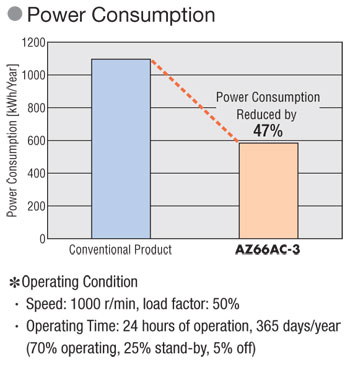

Energy Saving

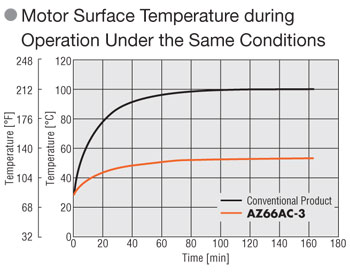

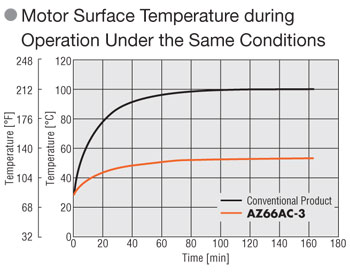

Heat generation is reduced thanks to the high efficiency motor, resulting in energy savings.

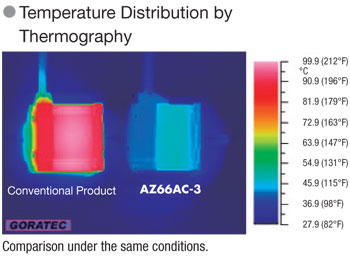

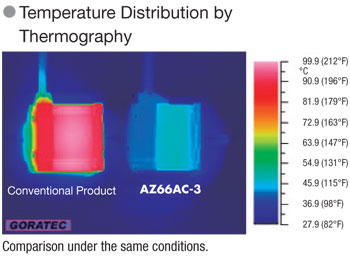

Lower Heat Generation

Heat generation by the motor has been significantly reduced through higher efficiency.