Feeding Materials

For applications where high speed operation and high resolution are required, a stepper motor or servo motor is the best solution. For speed stability, brushless DC speed control systems offer a range of solutions. While AC motors and speed control motors provide easy to use continuous motion.

Applicable Products

Position Control Systems

For conveyors that require higher accuracy positioning Oriental Motor offers a wide range of Stepper Motor and Servo Motor solutions. Stepper motors, with their ability to product high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance. Servo motors are easy to operate and allow for smooth operation with large inertial loads and belt mechanisms. Servo motors are ideal for positioning over long distances using a flat torque characteristic from low to high speeds.

Type |

Features |

|

|

Positioning over short distance |

Stepper Motors are suitable for high accuracy positioning over a short distance and provide high torque even at low speeds. Stepper motors also offer very low vibration and a wide range of features and options such as gearheads, encoders and built-in controllers to meet the specific needs of your application. |

Positioning over long distance |

Servo Motors provide accurate positioning for quick moves or for a long distance moves. All feature a closed loop configuration ideal for variable loads and offer a wide range of gear options and braking or load holding options. The built-in controller (stored data) FLEX also helps for system configuration considerations. |

|

Geared Options

A wide range of gearing options are available to provide higher permissible inertia, higher resolution positioning and higher torque for index table and high inertia applications.

Geared Stepper Motors |

Geared Servo Motors |

Geared stepper motors not only achieve deceleration, high torque and high resolution, but they are capable of driving larger inertial loads compared to a standard motor. A wide range of gearing options are available: |

The servo motor has restrictions on permissible load inertia, but the geared type can be used to greatly increase the load size that can be driven. |

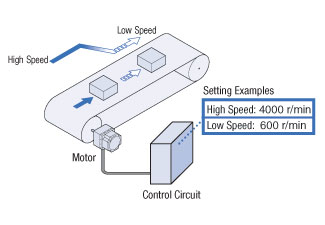

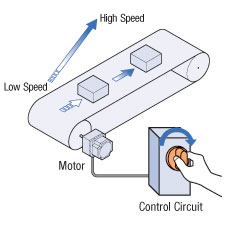

Speed Control Systems

For conveyors where the speed needs to controlled or vary during operation Oriental Motor offers Brushless DC Motors & Gear Motors (BLDC Motors) that offer a wide speed control range and constant torque regardless of load.

By combining a control circuit with the motor, speed changes can be performed. Speed control motors are optimal for switching between high speed and low speed operation and for arbitrary adjustment of speed.

Setting Multiple Speeds and Switching Speeds |

Arbitrarily Adjusting the Speed |

|

|

Type |

Features |

Output |

Speed Control |

Power |

|

Brushless DC Motors & Gear Motors (BLDC Motors) provide high speed stability, energy saving and space saving. Brushless DC motors also allow for stable speed control even with a fluctuating load and offer constant torque over a wide speed range. |

15 W (1/50 HP) |

80 ~ 4000 r/min |

Single-Phase 100-120 VAC Single-Phase 200-240 VAC Three-Phase 200-240 VAC 24 VDC 48 VDC |

Oriental Motor also offers a range of gear options to reduce the motor speed and generate greater torque.

Brushless DC (BLDC) Motor Gear Options

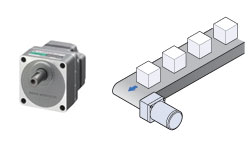

Parallel Shaft Gearheads |

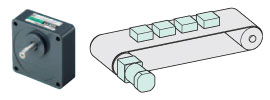

Hollow Shaft Flat Gearheads |

Parallel Shaft gearheads reduce the motor speed and generate greater torque. A wide range of gear ratios are available. |

Direct connection to the drive shaft is possible without using a connecting part which enables equipment space saving. In addition, the hollow shaft flat gearhead enables permissible torque without saturation even at high gear ratios, so the motor torque can be fully utilized. |

Fixed Speed Systems

For fixed speed or constant speed conveyors and conveyor systems Oriental Motor offers a wide range of AC gear motors.

AC induction motors are ideal for conveyor systems that operate continuously in one direction. For conveyor systems where the load must be held in place or for vertical applications, there are a wide range of AC motors with power-off activated electromagnetic brake. For simple braking, our AC Speed Control Motors or Brake Pack are also convenient options. The IP67 rated washdown AC induction motors are suitable for conveyors that will be in contact with water or need to be washed. Synchronous motors are also available for conveyors where the motor needs to be operated continuously in one direction at synchronous speed regardless of load torque; the low-speed synchronous motor is ideal for frequent starting, stopping and reversing.

Type |

Features |

Output Power |

Power Supply |

|

AC Induction Motors are suitable for applications where the motor is operated continuously in one direction. |

1 W (1/750 HP) |

Single-Phase 100-120 VAC Single-Phase 200-240 VAC Three-Phase 200-240 VAC |

|

AC Reversible Motors are suitable for applications where the motor reverses its direction repeatedly. |

1 W (1/750 HP) |

Single-Phase 100-120 VAC Single-Phase 200-240 VAC Three-Phase 200-240 VAC |

|

AC Motors with Electromagnetic Brake are suitable for applications where the load must always be held in place. |

6 W (1/125 HP) |

Single-Phase 100-115 VAC Single-Phase 200-230 VAC Three-Phase 200-230 VAC |

Type |

Features |

Output Power | Power Supply |

|

IP67 & IP65 Rated Washdown AC Induction Motors are suitable for applications where the equipment comes in contact with water or needs to be washed with water. |

25 W (1/30 HP) up to 3 HP |

Single-Phase 100-115 VAC Single-Phase 200-230 VAC Three-Phase 200-230 VAC |

|

Low-Speed Synchronous Motors are suitable for applications where the motor is operated starting, stopping and reversing repeatedly and the motor is operated at synchronous speed regardless of load torque. |

1.65 in. (42 mm) up to 3.35 in. (85 mm) |

Single-Phase 100-115 VAC |

Oriental Motor also offers a range of gear options to reduce the motor speed and generate greater torque as well as a brake pack for use with AC motors to allow for instantaneous stopping.

Parallel Shaft Gearheads |

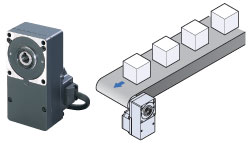

Right-Angle Gearheads |

Parallel Shaft gearheads reduce the motor speed and generate greater torque. A wide range of gear ratios are available. |

Right-Angle Gearheads are suitable for applications where space saving is required by allowing the motor to be mounted at a right-angle to the conveyor. Solid shaft and hollow shaft models are available. |

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)