The New Pentagon Bipolar Driver for 0.36°/0.72° Stepper Motors

Oriental Motor stepper motors with a step angles of 0.36° or 0.72° are wound in the bipolar New Pentagon configuration and, therefore, require a bipolar type driver. The New Pentagon bipolar driver allows the stepper motor to be driven at full step, half step and even microstep resolutions while ensuring that maximum torque is being generated by the motor on every step. This is a unique advantage for 0.36° or 0.72° stepper motors. The New Pentagon bipolar drive method also provides extremely smooth motion as well as maintaining torque and step accuracy regardless of the step resolution.

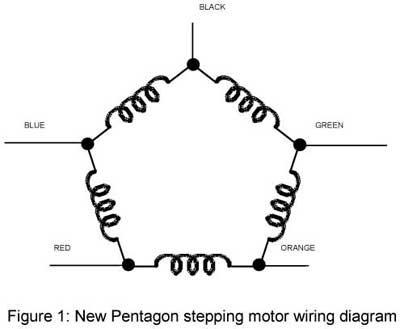

The New Pentagon motor/driver system is able to achieve this performance because the motor windings are all interconnected, as shown in the figure below. Since the coils are all interconnected, there is only one winding circuit that needs to be energized for the motor to operate. By having only one circuit to control, the driver can do a better job of controlling the amount of current in the motor, which leads to better torque stability and no loss of positioning accuracy as the microstepping resolution is increased.

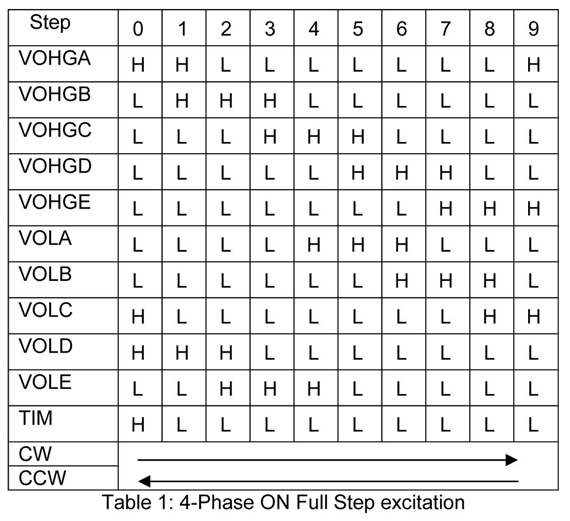

For a New Pentagon driver, there are 10 full steps in an electrical cycle with 4 phases being ON at any given time. Each full step results in 0.72° (0.36°) of shaft rotation. The 4–phase ON excitation state table is shown in table 1 below. An “H” represents that the respective MOSFET is active.

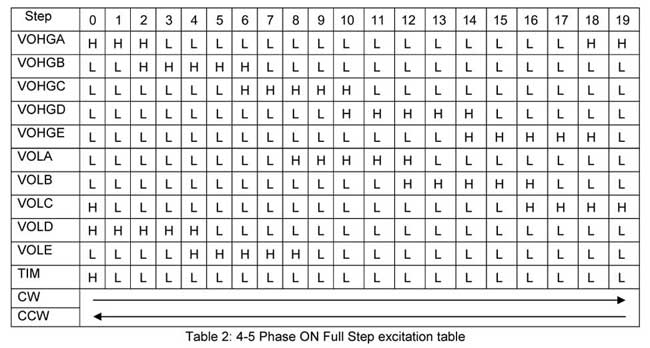

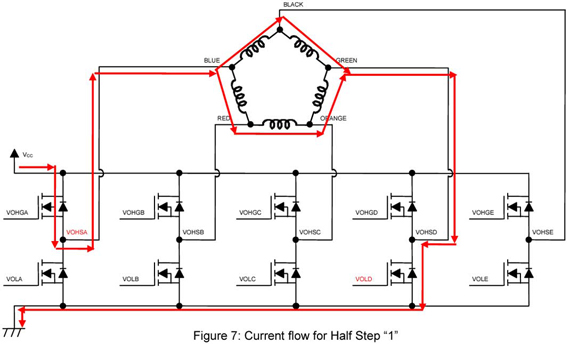

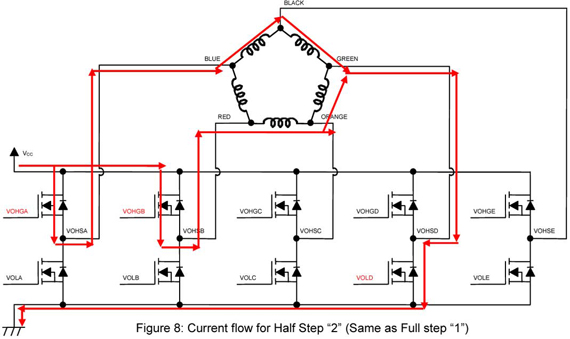

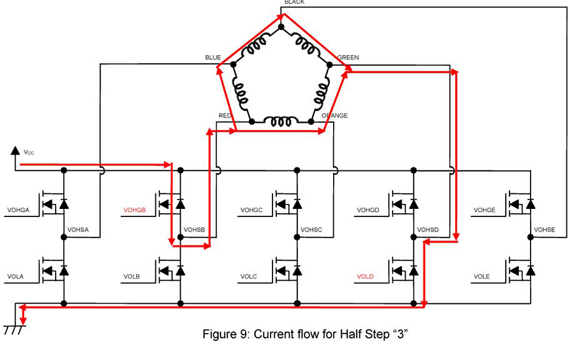

Half stepping, or 0.36°/step (0.18°/step), is possible by alternately turning 4-phases ON and then 5 phases ON. The 4~5-phase ON excitation sequence has 20 steps in its electrical cycle and is shown in table 2 below. An “H” represents that the respective MOSFET is active.

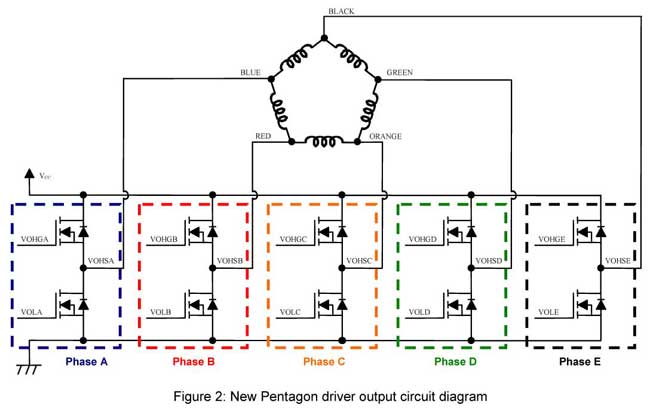

The output circuit diagram for a New Pentagon driver is shown in figure 2 below. The New Pentagon bipolar driver uses 10 transistors which are shown below. Simply stated, the 5 transistors shown in the top row determine which motor coils the voltage will enter the motor windings (High side) while the 5 transistors shown in the bottom row determine which motor coils the voltage will flow to ground through.

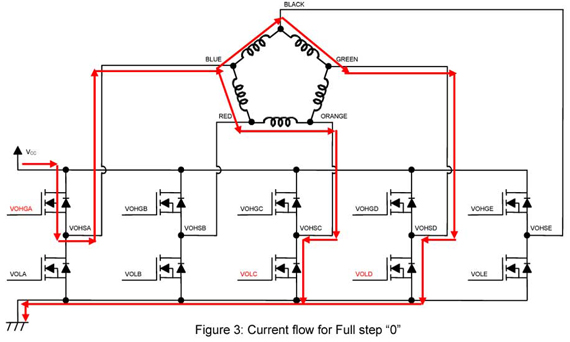

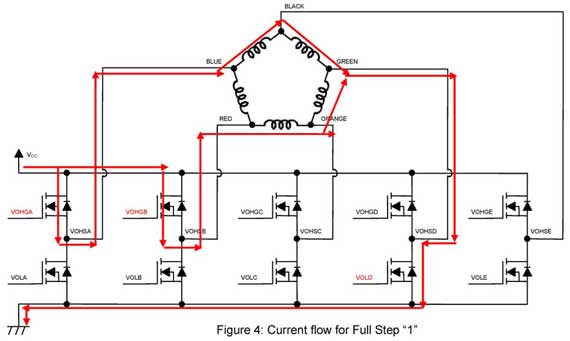

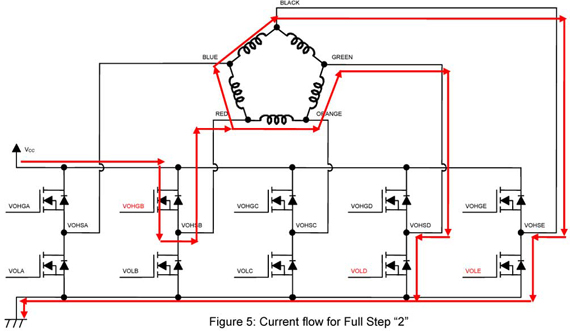

When the driver is first powered on or reset, the excitation state is set step 0. By referring to excitation state table 1, we can see that current will be flowing through the motor as shown in figure 3. Figures 4 and 5 show the current flow for Full steps 1 and 2, respectively.

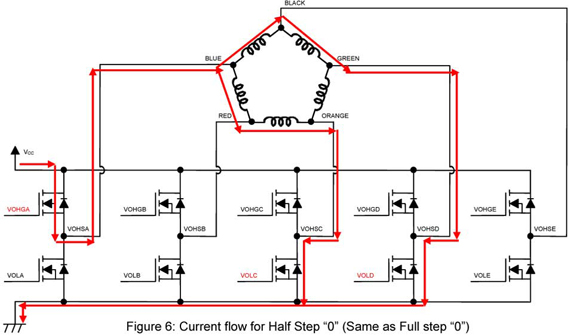

The current flow for the first three steps of Half stepping mode is shown in figure 6, 7 and 8.

Oriental Motor offers several different New Pentagon bipolar driver options. Which driver option you may choose is determined by several factors

-

1. What input voltage is available? Drivers are available that accept all common single and three phase AC power supplies as well as drivers that accept DC voltage input.

2. What motor shaft speed is required? Higher shaft speeds require higher applied voltage to the motor windings. AC power input versions of Oriental Motor drivers apply approximately 162VDC to the motor windings, allowing the motor to produce useful torque levels in excess of 4000 rpm. Items 1 and 2 go hand-in-hand. In some cases, an AC input driver may be the only option based on speed requirements.

-

3. What output torque is required? The amount of torque required for the application will determine the frame size and stack length of the stepper motor. The larger the motor, the higher the current per phase rating it will have. The output current capability of the driver can affect its size and how it should be the amount of cooling that may be required.

4. What motor resolution is required? The number of steps per revolution that the motor needs to take will also narrow down the search for which driver to use. Either a full/half step driver or a microstepping driver can be selected.

5. Does the driver need to be “intelligent”? Drivers will either accept step & direction commands from separate controller/pulse generator or it can be programmed to create its own motion profiles.

6. How much space is available for the driver? Drivers can be mounted either independently or incorporated into a circuit board design.

Nick Johantgen

North American Technical Product & Training Manager

Oriental Motor USA Corporation