How to Select a Cooling Fan

To properly select a particular fan for an application, the detailed requirements must be known. This article goes through the steps of selecting a cooling fan.

Cooling fans and blowers are essential to applications where temperatures must be maintained or withstand the presence of heat. In order to avoid problems, the appropriate cooling unit for these systems must be selected.

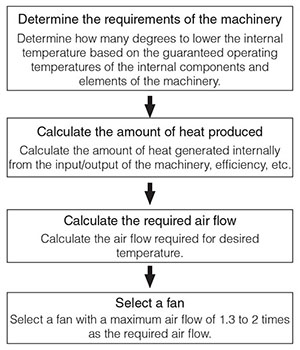

Fan Selection Procedure

Basic methods of selecting typical ventilation and cooling products based on their use.

Specifications and Conditions of the Machinery

Determine the required internal temperature of the machinery.

Heat Generation Within the Device

Determine the amount of heat generated internally by the machinery.

Calculate Required Air Flow

Calculate the air flow required once you have determined the heat generation, the number of degrees the temperature must be lowered and what the ambient temperature should be.

Selecting a Fan

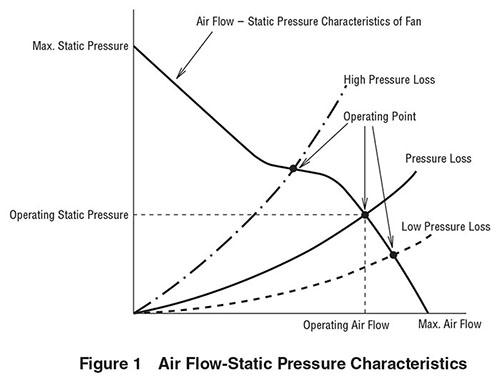

Select a fan using the required air flow. The air flow of a mounted fan can be found from the air flow – static pressure characteristics and the pressure loss of the machinery. It is difficult to calculate the pressure loss of the machinery, so a fan with a maximum air flow of 1.3 to 2 times as the required air flow may be used.

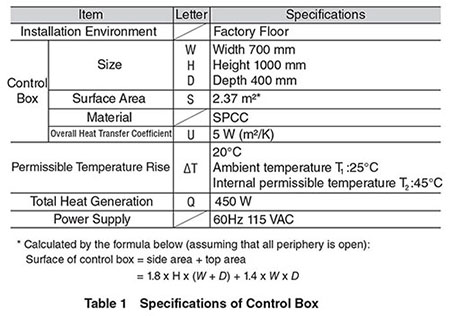

Example of Selection – Ventilation and Cooling of Control Box

Required Air Flow

The following explains a calculation method using the formula and a simple calculation method using the graph.

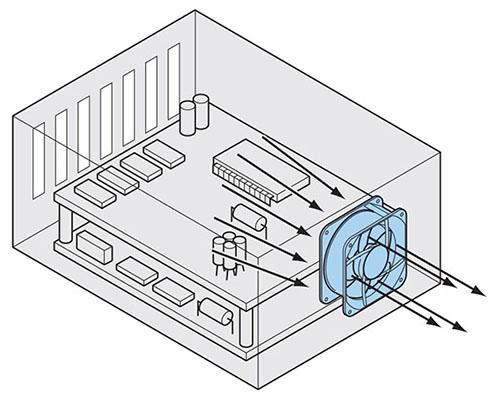

◊ Obtaining by Calculations

Internal pressure loss must be considered when calculating the required air flow. In general, pressure loss inside the control box is not known. Therefore, the air flow at the operation point is assumed as 50% of the maximum air flow and a safety factor Sf = 2 is applied.

1. Obtaining by Calculations

2. Search for the cross point A between heat generation Q (450 W) and permissible temperature rise ←T (20°C).

3. Draw a line parallel with the horizontal axis from point A.

4. Search for the cross point B between the parallel line and surface area S (2.37 m²) line.

5. Draw a line perpendicular to the horizontal axis from point B. Required air flow is approximately 0.5 m³/min.

6. Allow for a safety factor (Sf) of 2 times. Required air flow will be 1.00 m3/min.

Applicable Fan Sizing Example:

Based on the above, the MU Series MU925M-21

Fan type Examples: Ventilation, Cooling, Drying, and Suction

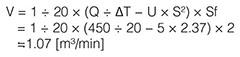

Device Ventilation and Cooling

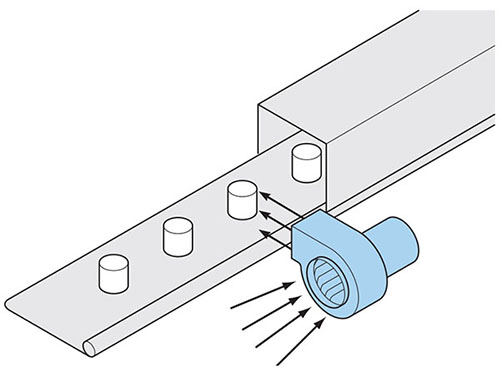

Air-Blow Cooling or Drying

Uniform Cooling or Drying