Brother Gearmotors NEMA C-Face Speed Reducers

Brother Gearmotors NEMA C-Face Speed Reducers

The gears in these NEMA C-Face speed reducers are high strength, maintenance free and can be mounted in any direction with their slip fit "O" ring design. Low to high reduction ratios, flange mount or foot mount types, right angle or hollow shaft right angle types available. Fit NEMA C-Face AC motors, brushless DC motors and brushed DC motors.

- For 1/2 HP up to 3 HP Motors

- NEMA C-Face, 140TC and 180TC input flanges

- Inline Helical Gear Speed Reducers

- Right-Angle Hypoid Gear Speed Reducers

NEMA C-Face Speed Reducers Lineup

Output Power |

Gear Type |

Input Power |

Gear Ratios |

Maximum Input Speed |

Parallel Shaft (Foot Mount) |

1/2 HP |

5:1 ~ 200:1 | 3600 r/min | |

Parallel Shaft (Flange Mount) |

||||

Right-Angle Hollow Shaft |

5:1 ~ 240:1 | |||

Right-Angle Solid Shaft |

5:1 ~ 240:1 |

*Torque and Speed vary based on input voltage and frequency, please review product specifications for details.

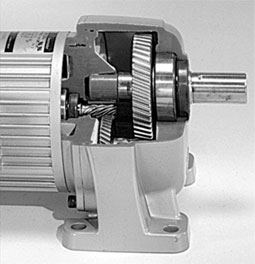

Parallel Shaft NEMA C-Face Speed Reducer - Brother Gearmotors Helical Gearing (G3 Series)

Longer Life

Compared to a spur gear of approximately the same pitch diameter, Helical gears can transfer high loads at greater speeds. This is due to the gradual engagement of the teeth and smooth transfer of the load.

Lightweight and Compact

Die cast aluminum gear housings make these speed reducers light in weight, allowing engineers to design more economical mounting provisions

Maintenance Free

High-quality synthetic grease is used in all gearboxes. They are filled at the factory and do not require maintenance filling or level checks. This saves valuable time at set up and eliminates concern for costly oil disposal required by the EPA.

Mount in Any Direction

These gearboxes are sealed with machine "slip" fit "O" rings and double lip spring shaft seals on both the motor and input shaft and output shaft driver. Thus, the gear motors can be mounted in any conceivable direction without concern for the position of a breather plug.

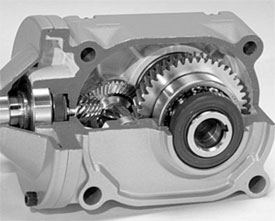

Right-Angle Hollow Shaft NEMA C-Face Speed Reducer - Brother Gearmotors Hypoid / Helical Gearing (F3 Series)

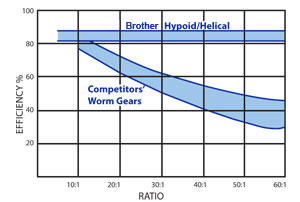

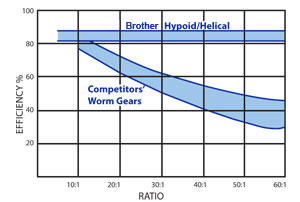

More Efficient / Longer Lasting

Hypoid gearing is up to 80% more efficient than worm gears. The all steel Hypoid/Helical combination had much better wear properties than softer bronze worm gearing and last longer and run cooler than worm gears.

High Reductions / Small Size

Gear reductions up to 1500:1 are available in most sizes. Hypoid gearing makes the high reduction significantly more compact and lightweight compared to worm/worm and helical/worm designs.

Mount in Any Direction

These gearboxes are sealed with machine "slip" fit "O" rings and double lip spring shaft seals on both the motor and input shaft and output shaft driver. Thus, these gear motors can be mounted in any conceivable direction without concern for the position of a breather plug.

Maintenance Free

High-quality synthetic grease is used in all gearboxes. They are filled at the factory and do not require maintenance filling or level checks. This saves valuable time at set up and eliminates concern for costly oil disposal required by the EPA.

Hypoid Gearing

Hypoid Gears are made of chromium molybdenum steel that has undergone precision carbonitriding. The superior efficiency, gear materials and heat treatment allows engineers to design-in the most compact gearmotor per output torque. These unique right-angle type gear motors have much higher power transmission efficiency than conventional worm gears. Growing demand is due to its COMPACTNESS, HIGH EFFICIENCY, and superior wear life, which meet the latest primary requirements for industrial applications.

Right-Angle NEMA C-Face Speed Reducer - Brother Gearmotors Hypoid Gearing (H2 Series)

Longer Life

Hypoid gear reducers use hardened steel gears throughout. This give Hypoid gearing far superior wear life compared to worm gears which use softer bronze on the output gear.

High Reductions / Small Size

Gear reductions up to 1200:1 are available in most sizes. Hypoid gearing makes the high reduction significantly more compact and lightweight compared to worm/worm and helical/worm designs.

Mount in Any Direction

These gearboxes are sealed with machine "slip" fit "O" rings and double lip spring shaft seals on both the motor and input shaft and output shaft driver. Thus, the gear motors can be mounted in any conceivable direction without concern for the position of a breather plug.

Maintenance Free

High-quality synthetic grease is used in all gearboxes. They are filled at the factory and do not require maintenance filling or level checks. This saves valuable time at set up and eliminates concern for costly oil disposal required by the EPA.

Hypoid Gearing

Hypoid Gears are made of chromium molybdenum steel that has undergone precision carbonitriding The superior efficiency, gear materials and heat treatment allows engineers to design-in the most compact gearmotor per output torque. These unique right-angle type gear motors have much higher power transmission efficiency than conventional worm gears. Growing demand is due to its COMPACTNESS, HIGH EFFICIENCY, and superior wear life, which meet the latest primary requirements for industrial applications.

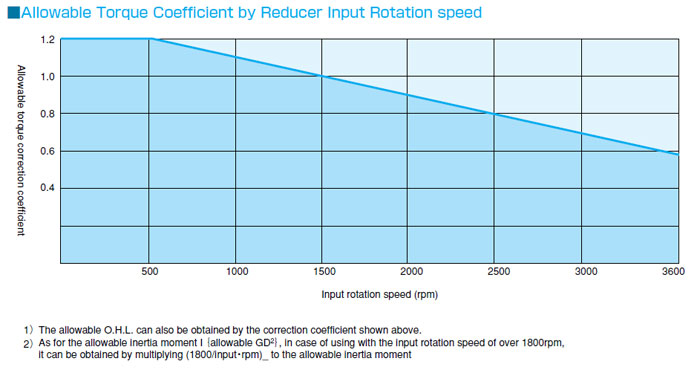

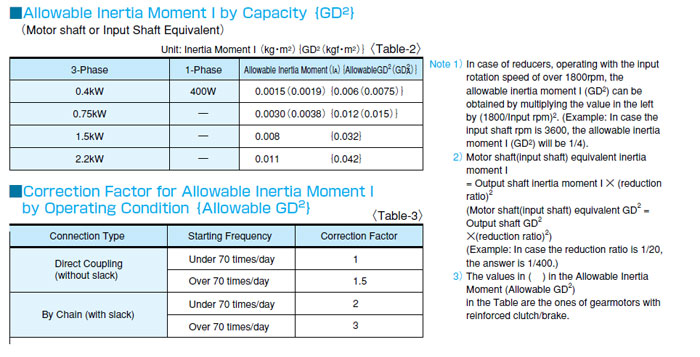

Allowable Torque

Gear reducers can be used with several types of motors. Use the chart and calculations below to determine the allowable shaft output torque, overhung load (OHL) an allowable inertia moment (GD2).

The values of output shaft torque in the product lineup table are the values when the input rotation speed is 1800 rpm. In case of using the motor with a different rotation speed, the output allowable torque can be obtained by multiplying the torque correction coefficient in the diagram below.

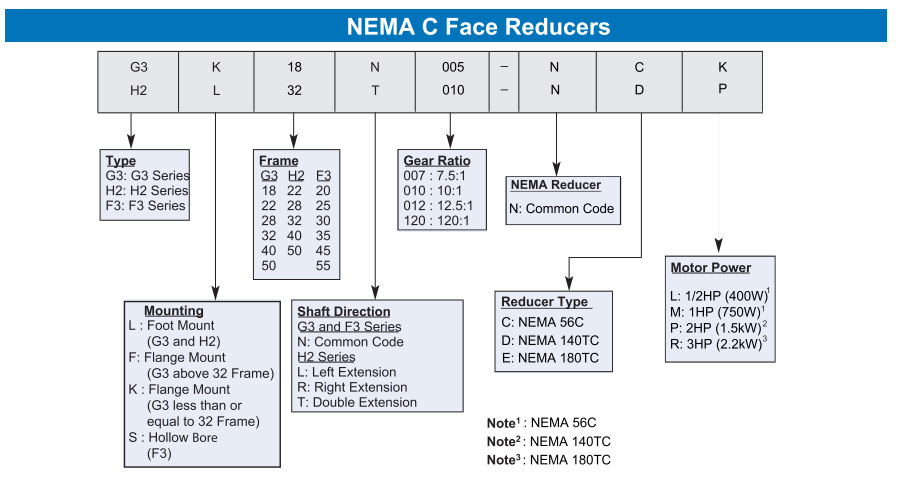

Part Number Code

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.