Brushless DC Motor 750 W (1 HP)

Brushless DC Motor 750 W (1 HP)

The 750 W (1 HP) brushless DC motors use a motor with a permanent magnet in the rotor. When combined with an inverter, speed control range of 300~4000 r/min is possible. In addition, an efficiency level IE5 is achieved, contributing to reduced electricity costs and CO2 emissions.

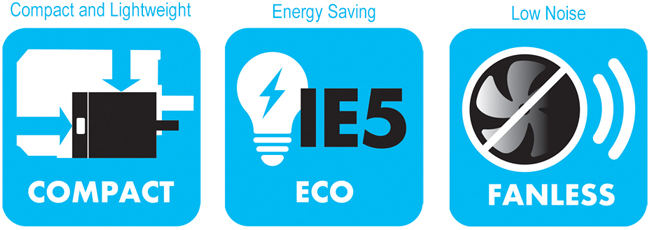

- Smaller and more lightweight compared to three-phase AC motors with the same output power

- Achieves efficiency class IE5, saves energy and reduces electricity costs

- Fanless and low noise

- Operates in combination with an inverter

- Applications: pumps, agitators, conveyors, processing machines

*Connection Cable Required

Compact, Energy-Saving, Low Noise Brushless DC Motor 750 W

The brushless DC motor 750 W (1 HP) type uses a PM motor with a permanent magnet in the rotor. When combined with an inverter, speed control range of 300~4000 r/min is possible. It is smaller and lighter than a three-phase AC motor, reducing the burden on assembly workers. In addition, achieves an efficiency level IE5, contributing to reduced electricity costs and CO2 emissions.

- Significantly reduced motor size

- Contributes to making equipment more compact

- Achieved IE5 level

- Reduced electricity costs

- Fanless design reduces noise level

- In addition, no scattering of dust and other particles

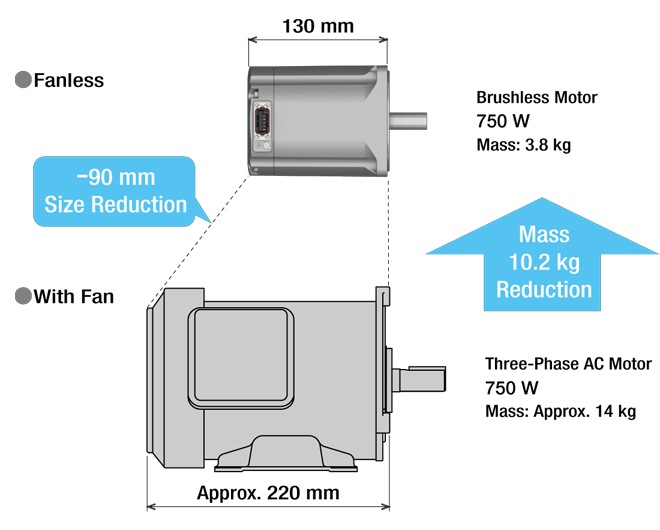

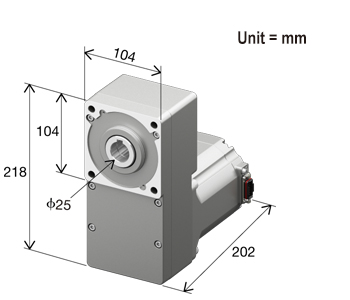

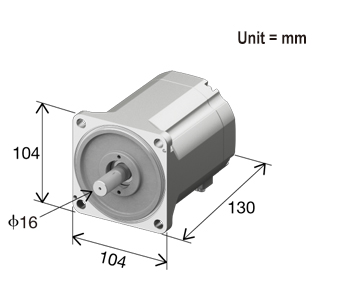

Smaller and Lighter Compared to Three-phase AC Motors With the Same Output Power

Brushless DC motors use permanent magnets in the rotor, making them highly efficient, compact, and lightweight. In addition, the fanless structure has been achieved due to its high efficiency and low heat generation. It contributes to reducing equipment size and reducing the burden on workers.

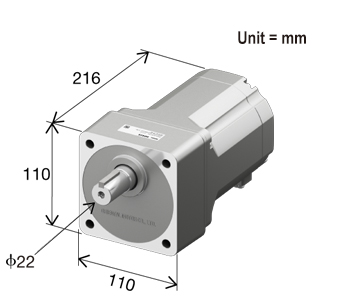

Motor Size (mm)

|

|

|

|---|---|---|

Parallel Shaft Gearhead

|

Hollow Shaft Flat Gearhead Mass: 8.4 kg |

Round Shaft Mass: 3.8 kg |

Achieves Efficiency class IE5, Saves Energy and Reduces Electricity Costs

This motor that satisfies the efficiency class IE5* for speed control motors. Contributes to reducing electricity costs and CO2 emissions.

*Efficiency standard value (%) for speed control motors (rated speed 1801-6000 r/min) based on the international standard IEC TS 60034-30-2.

Energy Saving Effect (Reference value for 1 unit)

Electricity costs and CO2 emissions can be reduced compared to 750 W induction motor (IE3).

| Brushless DC Motor 750 W + Inverter |

IE3 Standard Value (82.5 %)* Induction Motor 750 W |

Annual Reduction | |

|---|---|---|---|

| Annual Electricity Consumption | Approx. 7400 kWh/year | Approx. 7960 kWh/year | 560 kWh/year decrease |

| Annual Electricity Cost | Approx. $1158/year | Approx. $1247/year | $89/year decrease |

| Annual CO2 Emissions | Approx. 3380 kg/year | Approx. 3640 kg/year | 260 kg/year decrease |

*Efficiency standard value (%) for induction motors (4 poles, 50 Hz) based on the international standard IEC 60034-30-1.

[Operating Conditions]

Operating Hours: 24 hours/day, 365 days/year

Electricity Rate Coefficient: 22.68 JPY/kWh

CO2 Coefficient: 0.457 kg/kWh

Electricity costs are calculated from Japanese yen to US dollars at 145 yen to $1.

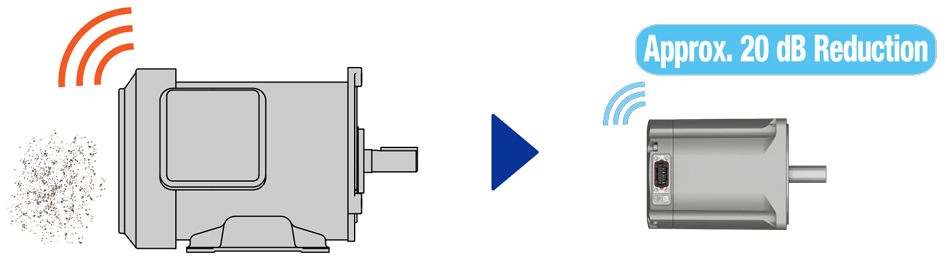

Fanless and Low Noise

Brushless DC motors have the fanless structure due to its high efficiency and low heat generation. The noise level is reduced by approximately 20 dB when compared to a three-phase AC motor with fan.

Measurement Conditions

- No load

- Speed: 1500 r/min

- Measured at position 15 cm from the back of the motor

Reduces the Scattering of Dust and Other Particles Because of Fanless

In the case of a motor with a fan, the cooling fan generates wind, which may scatter dust and other particles in the surrounding area. Brushless DC motors are no risk of dust dispersal because of fanless.

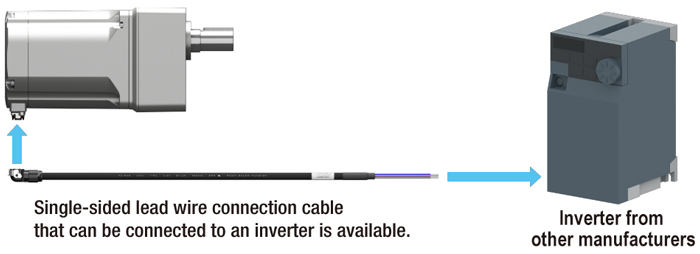

Operates in Combination With an Inverter

Brushless DC motors are three-phase motors and can be controlled in combination with an inverter.

Note

Combinable inverters are inverters that can be combined with PM motors.

*This cable is only available for the shaft side direction

- Speed control is possible (300~4000 r/min)

- Functions installed in the inverter can be used

- Network control is possible by using a network compatible inverter

- Reducing the effort required for installation and modification due to the inverter currently in use can be used.

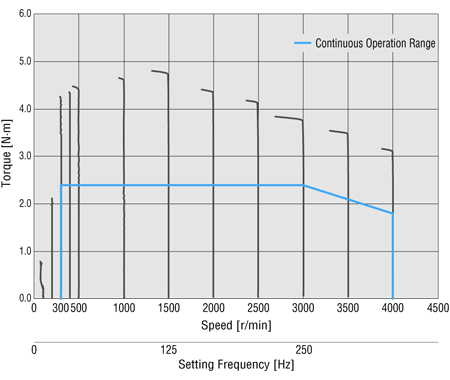

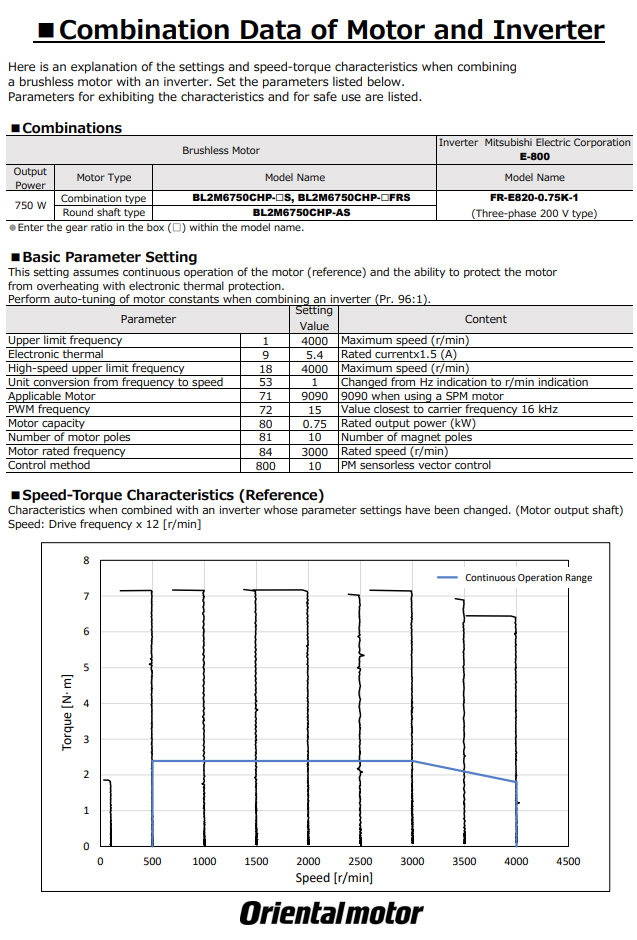

Combination Characteristic Example

Products for Combination

| Brushless DC Motor | Inverter |

|---|---|

| BL2M6750CHP-AS (750 W) | Mitsubishi Electric Corporation E800 |

Basic Parameter Setting

This setting is based on the assumption that continuous operation of the motor (for reference) and that capable of protecting the motor from overheat protection by the electronic thermal. When combining, perform automatic tuning of the motor constants (Pr. 96: 1).

| Parameters | Setting Value | Description | |

|---|---|---|---|

| Upper Frequency | 1 | 4000 | Maximum Speed (r/min) |

| Electronic Thermal | 9 | 5.4 | Rated current × 1.5 (A) |

| High-Speed Upper Limit Frequency | 18 | 4000 | Maximum Speed (r/min) |

| Frequency/Speed Unit Conversion | 53 | 1 | Changed from Hz notation to r/min notation |

| Applicable Motor | 71 | 9090 | 9090 for SPM motors |

| PWM Frequency | 72 | 15 | Closest value to 16 kHz carrier frequency |

| Motor Capacity | 80 | 0.75 | Rated output power (kW) |

| Number of Motor Poles | 81 | 10 | Number of magnet poles |

| Motor Rated Frequency | 84 | 3000 | Rated speed (r/min) |

| Control Method Selection | 800 | 10 | PM sensorless vector control |

Speed - Torque Characteristics (Reference values)

Characteristics when combined with an inverter with adjusted parameter settings. (Motor output shaft)

Connector Type for Easy Connection

Cable connection is easy due to the locking lever that does not require screw fitting. Reduces the hassle of connecting cables during motor installation and maintenance.

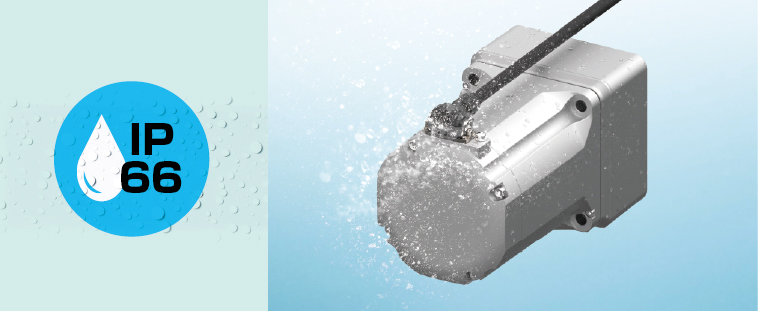

Safe Even in Environments Where Water Splashes (IP66 rating)

*The mounting surface of the round shaft type is not IP66.

Product Lineup

| Output Power | Gear Options | Voltage Class [V] |

Frame Size [mm] |

Speed Range | IP Classification |

|---|---|---|---|---|---|

Parallel Shaft Gearhead Hollow Shaft Flat Gearhead Round Shaft (No Gearhead) |

Three-Phase 200 VAC | 110 | 300~4000 r/min (The minimum speed depends on the inverter to be combined.) |

IP66 (Excluding mounting surface for Round Shaft type) |

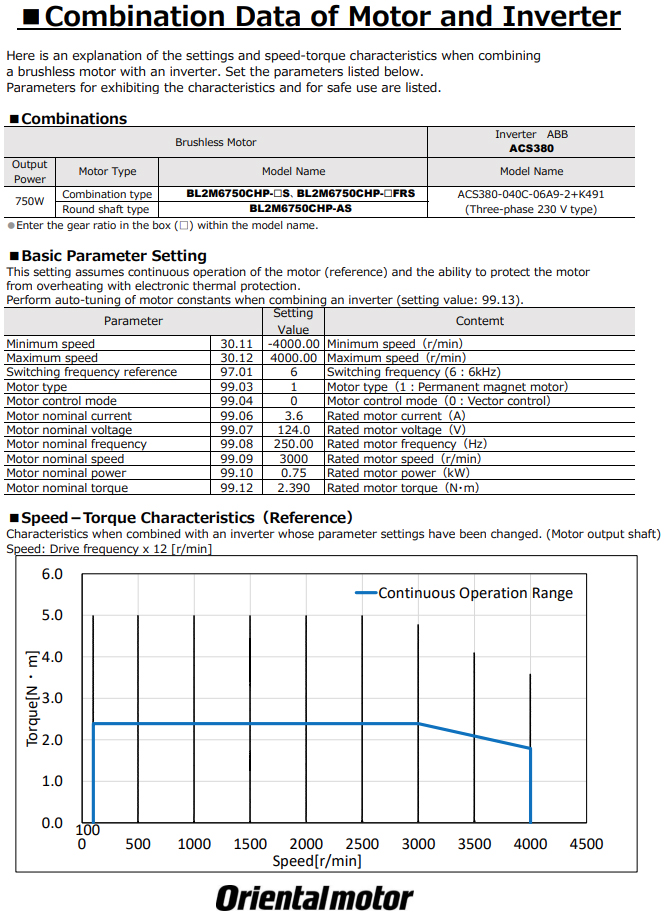

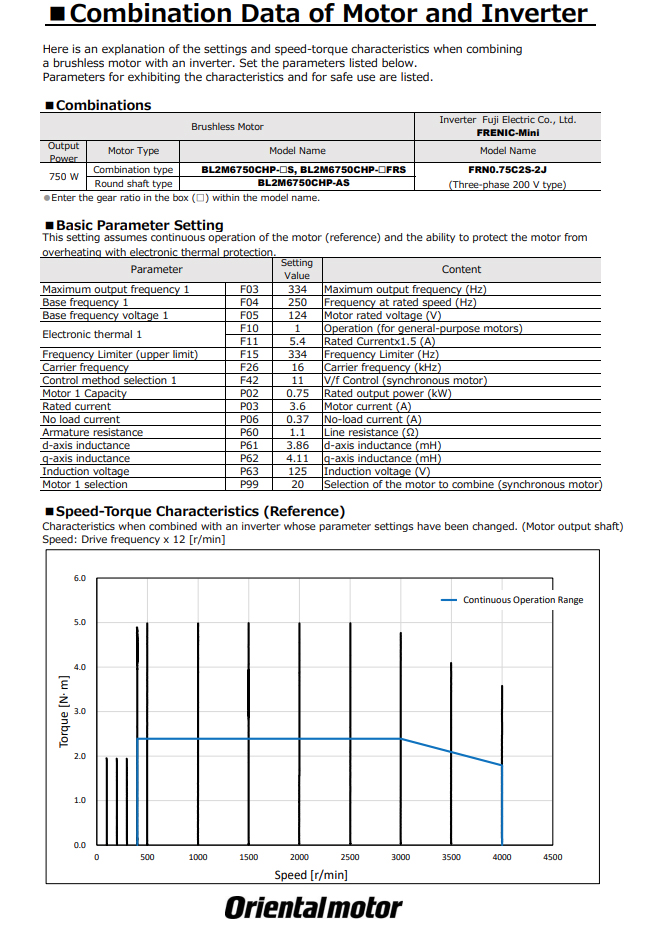

Performance with Inverters/VFDs

Performance Examples with ABB

ACS380

Performance Examples with Fuji

FRENIC-Mini

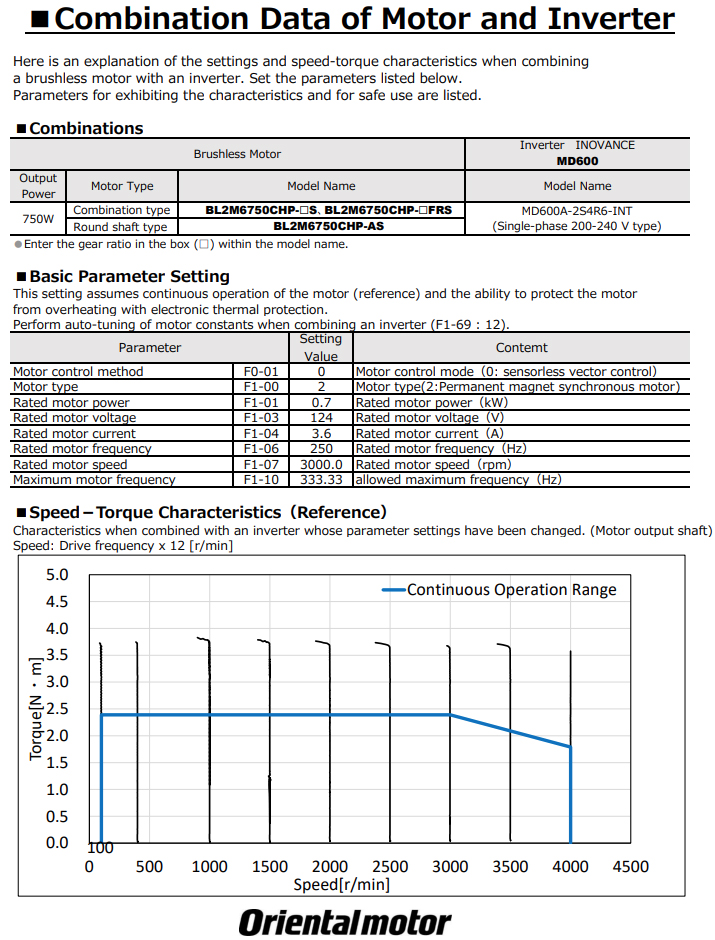

Performance Examples with Inovance

MD600

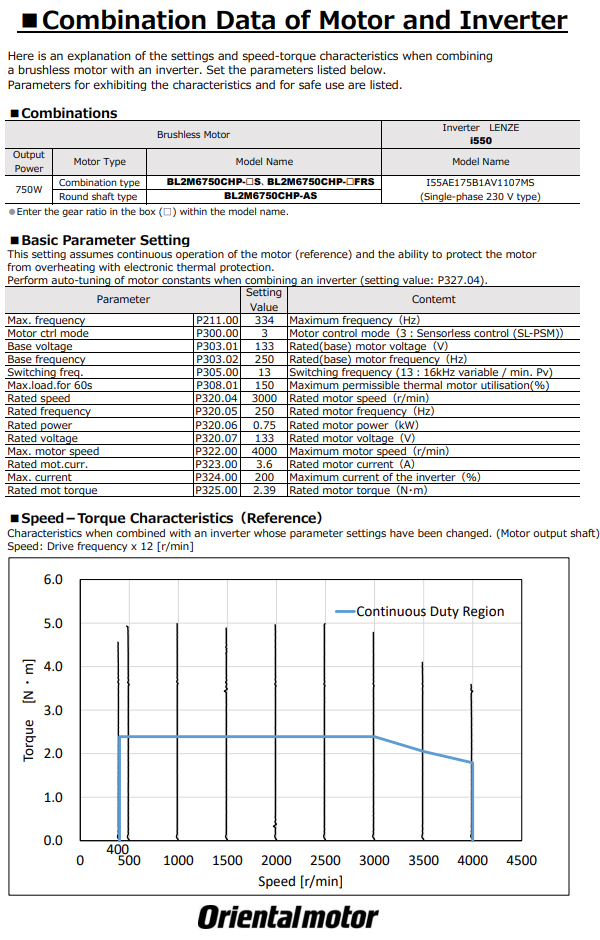

Performance Examples with Lenze

i550

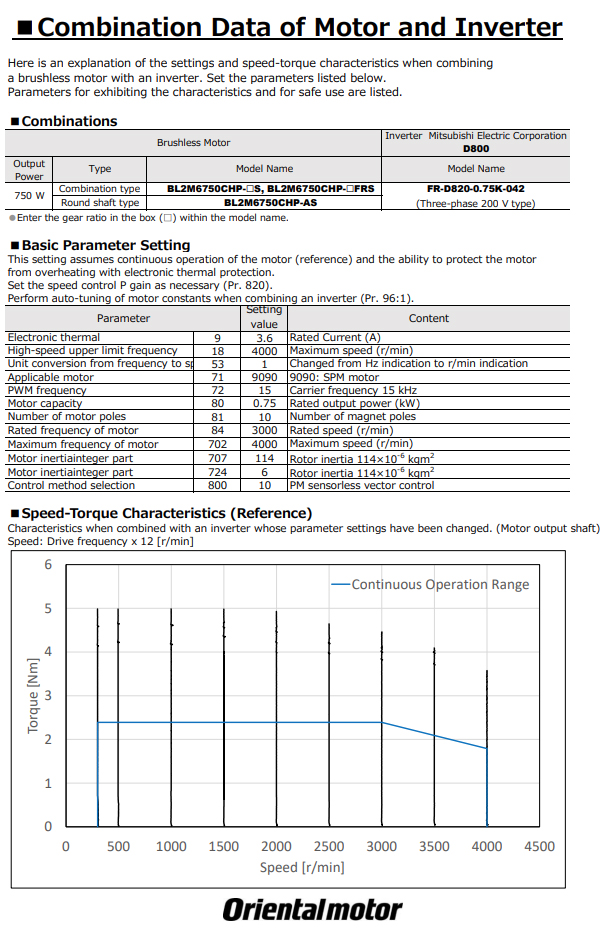

Performance Examples with Mitsubishi

D800

E-800

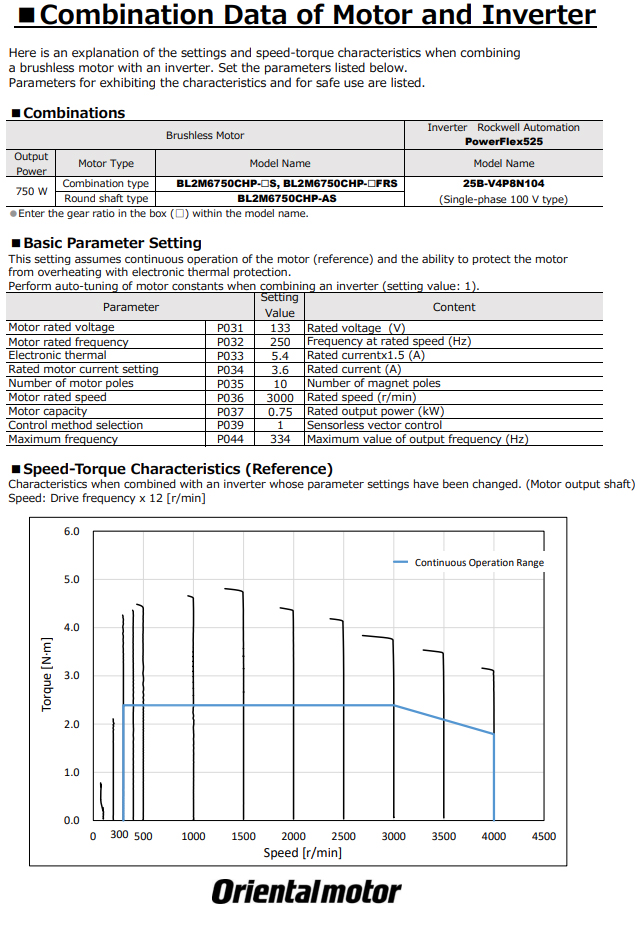

Performance Examples with Rockwell

PowerFlex525

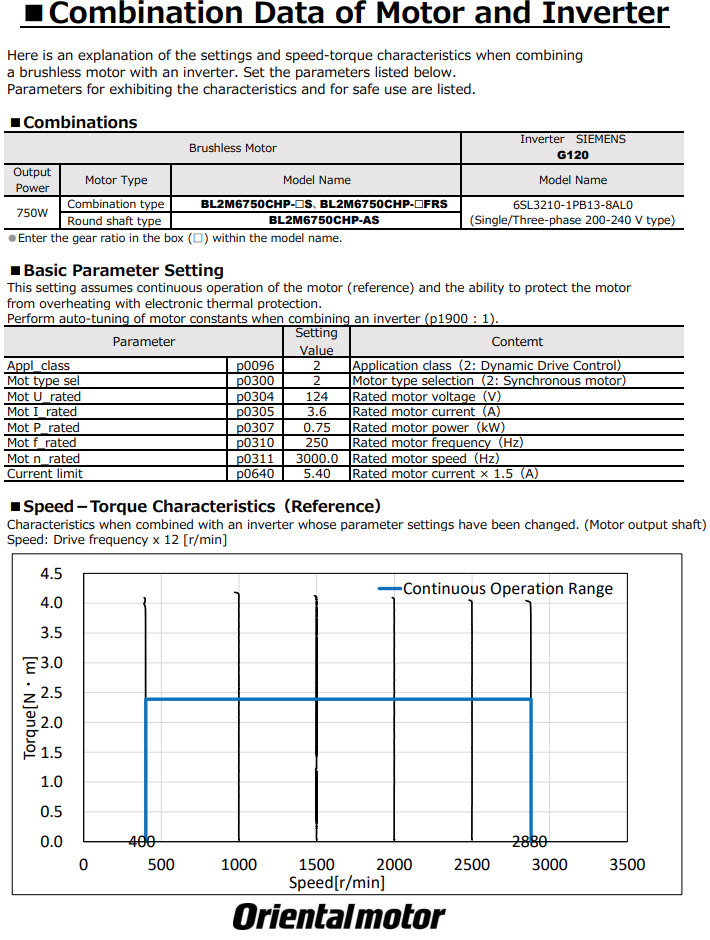

Performance Examples with Siemens

G120

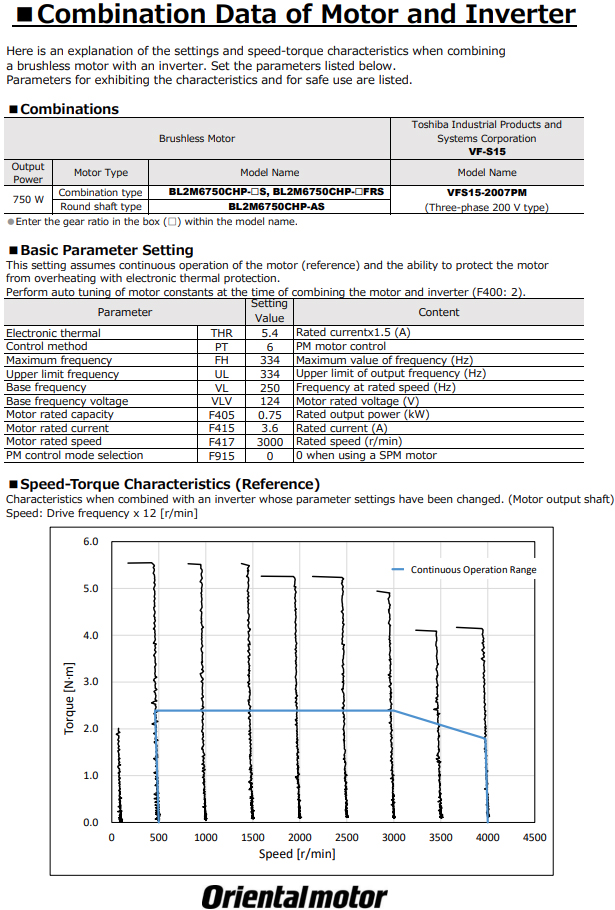

Performance Examples with Toshiba

VF-S15

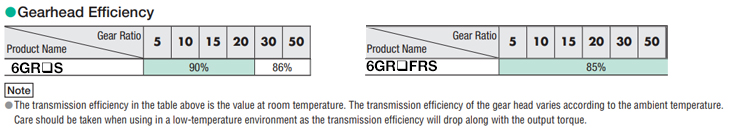

Permissible Torque refers to the value of load torque driven by the gearhead's output shaft. Each value is shown for the corresponding gear ratio.

Please use the formula below to calculate the permissible torque value.

Permissible torque TG = TM × i × η

TG: Permissible torque of gearhead

TM : Motor torque (Use 2.39 N·m from BL2M6750CHP-AS)

i : Gearhead gear ratio

η : Gearhead efficiency

Connection Cable

Dedicated connection cable (connection terminals, 0.5 m (1.6 ft.)) to connect a 750 W (1 HP) BLS Series Brushless DC Motor to the inverter.

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

Mounting Bracket

For 104 mm and 110 mm frame size.

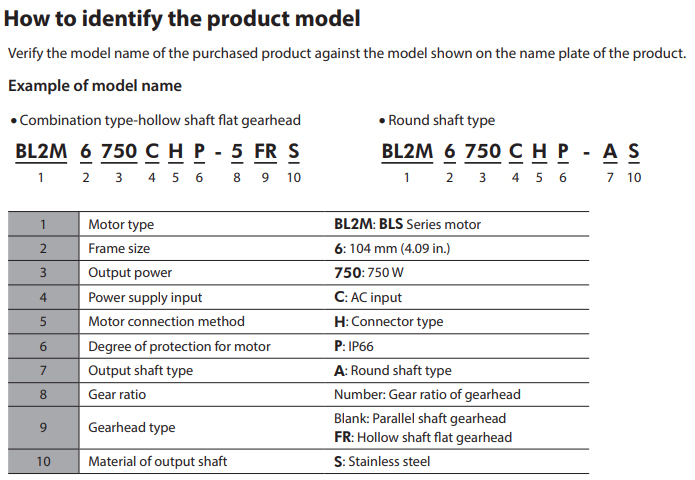

Part Number Code

Applications

Conveyor (Chain conveyor)

Agitator

Crusher

Pump

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.

Videos

Technical Articles

Reference