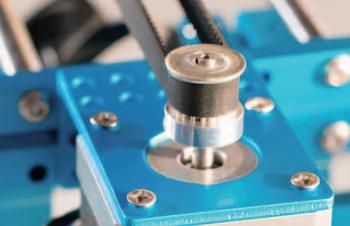

Industries > Medical > Medical Application - Pick and Place (Belt Pulley)

Medical Application - Pick and Place (Belt Pulley)

Placement of medical samples requires high positioning accuracy and reliability. Detecting the speed and position of motors is a critical step in maintaining precision and avoiding errors. Designing a belt pulley system requires appropriate motors with the right permissible radial load to handle belt tension. For stepper motors, it is also important to consider the jumping of the teeth and have a way to detect or correct the error.

Common Requests

- High overhung load

- Low vibration

- Monitoring position and errors

Solutions

Detecting Feedback through Motor Encoder

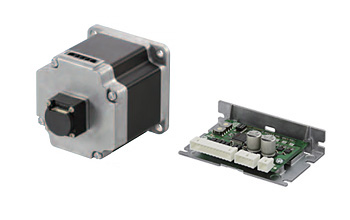

PKP Series 2-Phase Stepper Motors Encoder Type and CVD Series Drivers

- High-torque stepper motors

- Use the Encoder Type for closed-loop operation for reliability (line driver only)

- Best performance when combined with CVD drivers

Detecting Feedback through Add-on Encoder on the Machine

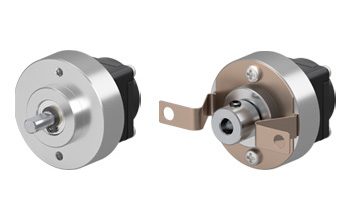

Rotary Encoders

- Small, thin, lightweight, high-resolution incremental encoder

- Install a rotary encoder on a mechanism

- Actual position, speed and rotation direction of the mechanism can be detected

Engineering Notes

Video

Product Guide for Medical Applications

We're Here to Help

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-468-3982