Hollow Rotary Actuators - DH Series

Hollow Rotary Actuators - DH Series

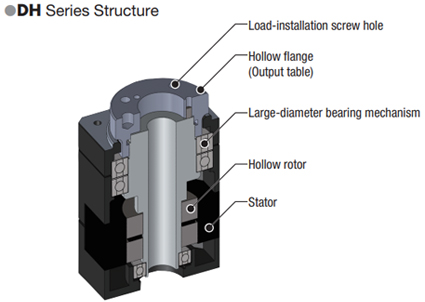

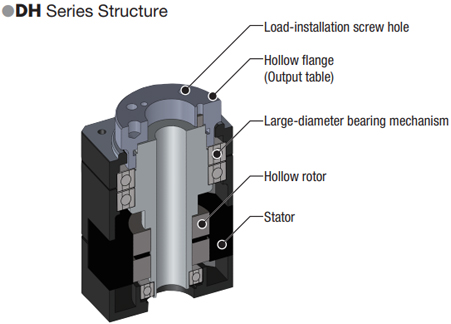

The DH Series is a line of products that combine a hollow flange with 5-phase stepper motor for applications that are sensitive to vibration or noise. It retains the ease of use of an open-loop stepper motor while also allowing for precise positioning in a compact and lightweight design.

- Reduce design time

- Parts cost reduction

- Reduce assembly man-hours

- Reduced time for precision adjustment

- Reduce maintenance time

- Requires CVD 5-Phase Stepper Motor Drivers

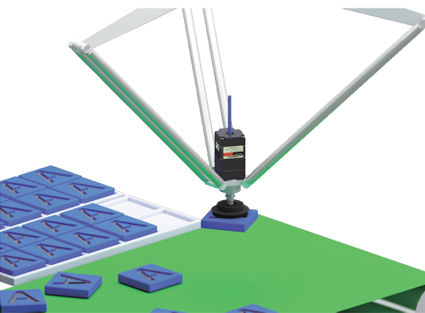

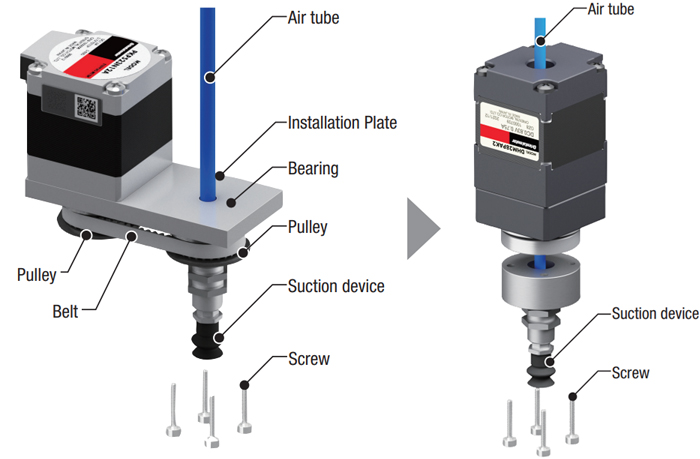

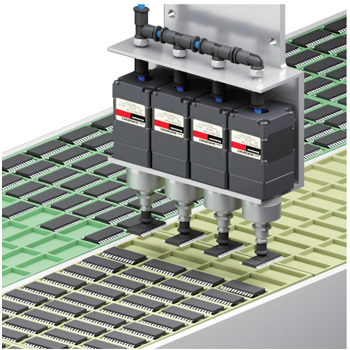

Hollowness Simplifies Piping and Wiring at the End of the Equipment

This actuator is a 5-phase stepper motor with a hollow flange. Air piping, wiring, and rays are passed through the hollow section, contributing to a simplified design, smaller size, and lighter weight at the end of the equipment.

θ Axis of Adsorber

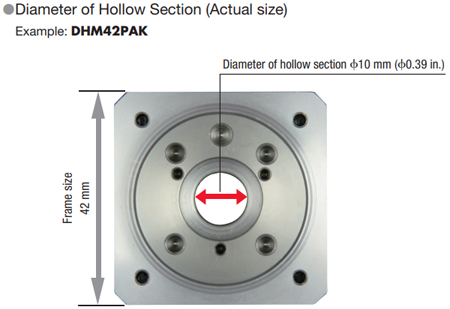

| Product Name | Frame Size | Diameter of Hollow Section | Mass |

|---|---|---|---|

| DHM28PAK2 | 28 mm | 5.2 mm | 0.17 kg |

| DHM42PAK | 42 mm | 10 mm | 0.47 kg |

Flange installation reduces the number of parts around the moving parts

The hollow flange can be attached directly to the load. This reduces the number of parts around the moving parts.

Some of the conventional parts have been eliminated, so the time required for equipment design and product selection is shortened.

Furthermore, the number of man-hours required for assembly and the adjustment of installation accuracy can be reduced, contributing to higher productivity.

|

Advantages of using the equipment

|

|---|

Advantages of using the equipment

- Less design time

- Lower parts cost

- Less aseembly work

- Less accuracy adjustment time

- Less maintenance time

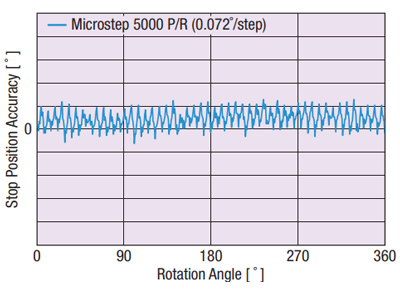

High Positioning Accuracy

The on-board 5-phase stepper motor allows for high positioning accuracy and fine operations to be stably repeated. Thanks to the microstep drive and smooth drive function in combination with the CVD driver, vibration is reduced at low speed and smooth operation is possible. Because the hollow flange does not use any transfer mechanisms like couplings or belts, there is no effect of error on accuracy caused by part rigidity or combination.

Advantages of using the equipment

|

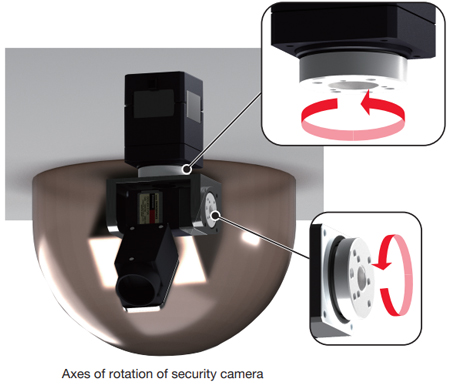

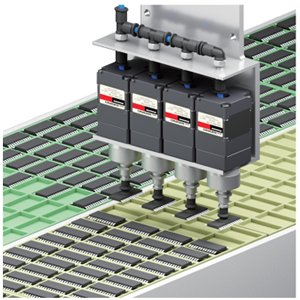

Part mounter Part mounterθ axis of parallel suction device |

Advantages of using the equipment

- Less design time

- Lower parts cost

- Less aseembly work

- Less accuracy adjustment time

- Less maintenance time

θ axis of parallel suction device

| Product Name | Stop Position Accuracy | Repetitive Positioning Accuracy |

|---|---|---|

| DHM28PAK2 | ±0.33˚ | ±0.15˚ |

| DHM42PAK | ±0.11˚ | ±0.05˚ |

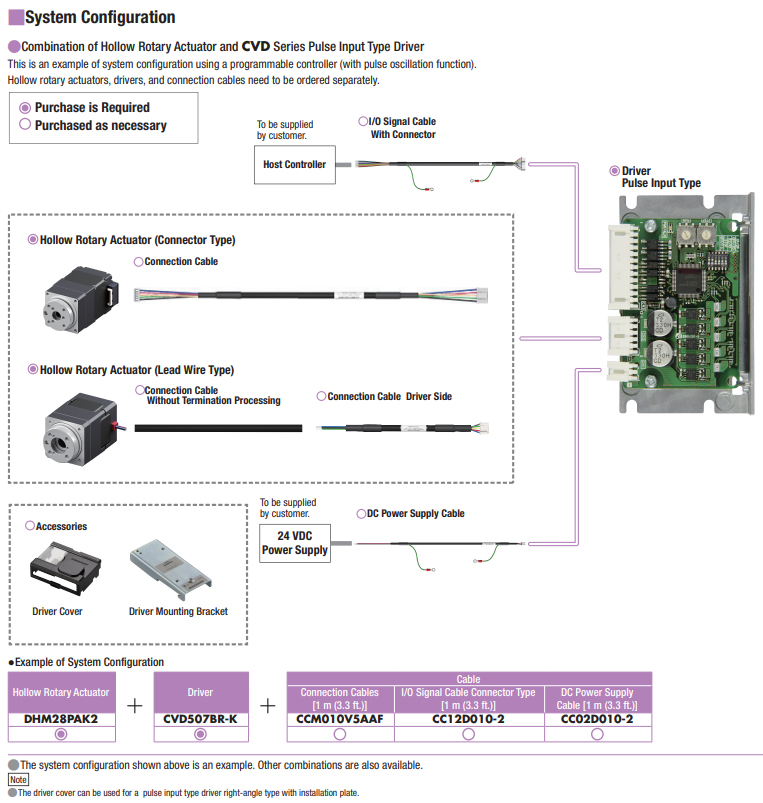

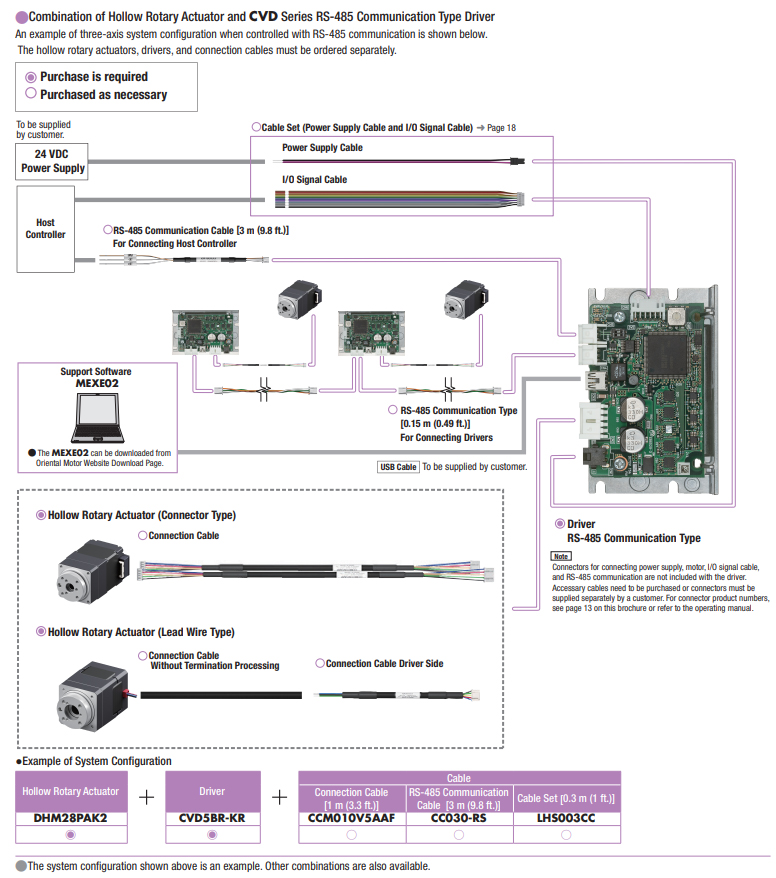

3 Selectable Driver Types

| Pulse Input | RS-485 Communication | Fully Closed-Loop Control |

|---|---|---|

|

|

|

|

|

|

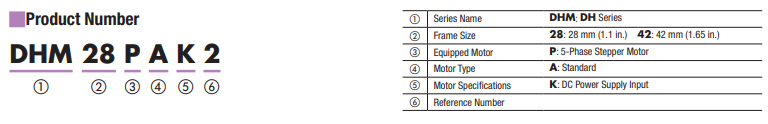

Product Lineup

| Frame Size | Diameter of Hollow Section | Stop Position Accuracy | Repetitive Positioning Accuracy | Maximum Holding Torque |

|---|---|---|---|---|

|

5.2 mm ( 0.20 in.) | ±0.33˚ | ±0.15˚ | 0.029 N·m (0.26 lb-in.) |

|

10 mm ( 0.39 in.) | ±0.11˚ | ±0.05˚ | 0.175 N·m (1.55 lb-in.) |

Connection Cables / Flexible Connection Cables

Frame Size 28 mm (1.1 in.)

These cables directly connect a connector-coupled motor and driver. A motor and driver can be directly connected using the connectors on both ends.

Frame Size 42 mm (1.65 in.)

These cables are used to connect the motor and the driver. There is a connector on the driver side.

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.

Downloads