αSTEP AZ Series Closed Loop, Absolute Stepper Motors

αSTEP Hybrid Step-Servo

Mechanical Absolute Encoder Stepper Motors

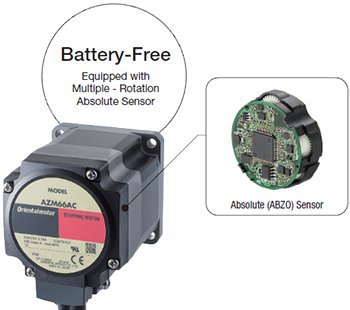

The αSTEP AZ Series stepper motors offers high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires αSTEP AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- Closed Loop Performance, No Hunting or Gain Tuning

- AC or DC Input Types

- Wide Range of Gear Types for Inertia Matching & Higher Torque

- Linear & Rotary Actuators

- Electromagnetic Brake Type Available

- AZ Series Stepper Motor Driver Required*

Mechanical Absolute Encoder

Advanced Technology at Affordable Prices

Oriental Motor has developed and patented a compact, low-cost, battery-free mechanical type absolute sensor. The αSTEP AZ Series is available at affordable prices and can contribute to improved productivity and cost reductions.

Mechanical-Type Encoder (No Battery Required)

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears. As a result, it does not require a battery.

Multiple-Rotation Absolute System*

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the home position.

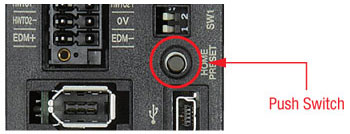

Home Setting Method*

The home position can be easily set by pressing a switch on the drivers surface, which is saved by the Mechanical Absolute Encoder. In addition, home setting is possible with the MEXE02 data setting software or external input signal.

Home position is easy to adjust by moving the motor to a desired position manually.

*Requires AZ Series Driver

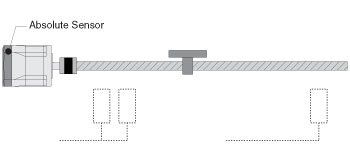

No External Sensors Required

Positional information is managed mechanically. External sensors such as home sensor and the limit sensor are not needed.

Reduced Cost

Sensor costs and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified and the degree of freedom for equipment design is increased.

Not Affected by Sensor Malfunctions

There is no concern about sensor malfunctions (when operating in environments filled with oil mist or filled with metal pieces due to metal processing), sensor failures or sensor wire disconnections.

Improved Return-to-Home Accuracy

Home position accuracy is increase because the return-to-home operation is performed regardless of any variations in home sensor sensitivity.

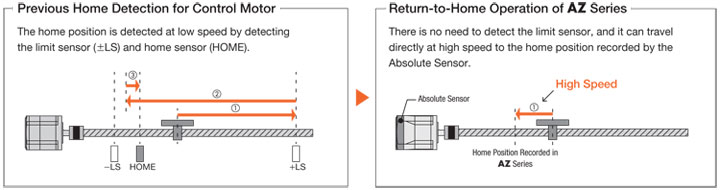

Shortened Reset Time - High Speed Return-to-Home

Because return-to-home is possible without an external sensor, return-to-home can be performed at high speed without taking the sensor sensitivity into account, allowing for a shortened machine cycle.

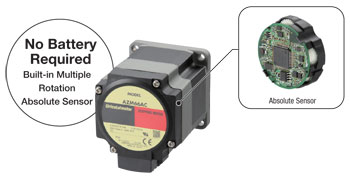

No Battery Required

No battery is required thanks to a mechanical-type sensor. Because positioning information is managed mechanically by the Mechanical Absolute Encoder, the positioning information can be preserved, even if the power turns off, or the cable between the motor and the driver is disconnected.

Reduced Maintenance

Because there is no battery that needs replacement, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Mechanical Absolute Encoder does not require a battery, so there is no limit to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

Position Holding Even when the Cable between the Motor and Driver is Detached

Positioning information is stored within the Mechanical Absolute Encoder.

*Because the positioning information is stored in the Mechanical Absolute Encoder, the home position must be reset if the motor is replaced.

High Reliability

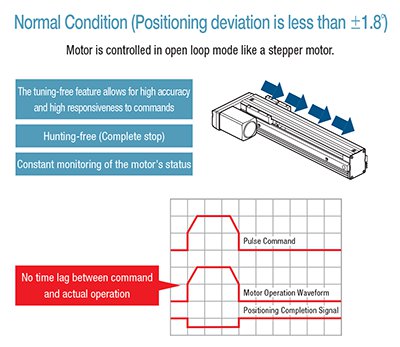

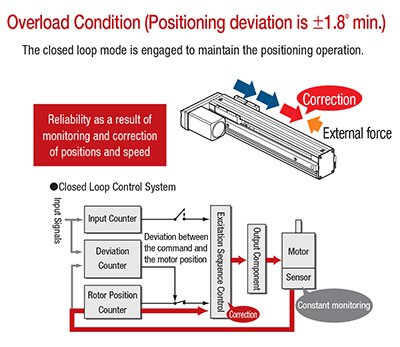

High Reliability is provided by using the control method unique to Oriental Motor that combines the merits of both open loop control and closed loop control.

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

In normal conditions, it operates synchronously with pulse commands under open loop control, and because of its compact size and high torque generation, it has excellent acceleration performance and response. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If a continuous overload is applied, an alarm signal is output. Also, when the positioning is completed, a signal is output. This provides high reliability.

No Tuning Required

Because it is normally operated with open loop control, positioning is still possible without gain tuning even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Holding the Stop Position

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

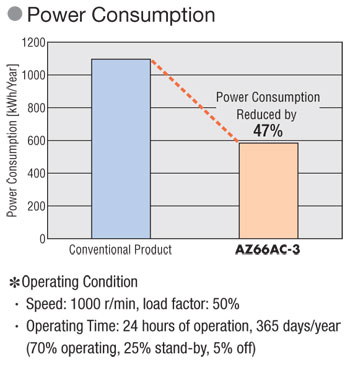

Energy Saving

Heat generation is reduced thanks to the high efficiency motor, resulting in energy savings.

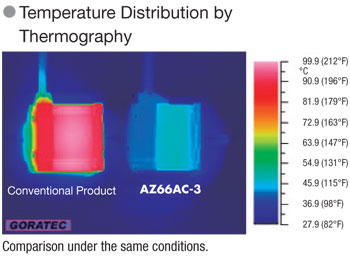

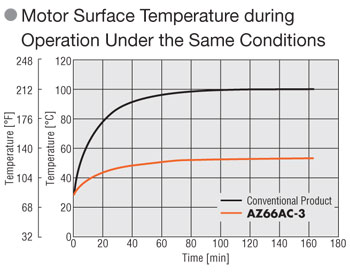

Lower Heat Generation

Heat generation by the motor has been significantly reduced through higher efficiency.

Product Types

Eliminate Extra Sensors with a Battery-Free Absolute System

The αSTEP AZ Series Mechanical Absolute Encoder is available as a leading closed loop, battery free absolute motion solution sold as a Stepper Motor + Driver, Linear Actuator and Rotary Actuator packages allowing for absolute, battery free, advanced performance across a wide range of applications. All αSTEP AZ Series products offer guaranteed performance are available in EtherNet/IP™, EtherCAT, Pulse Input, Built-In Controller (Network) Types in AC or DC Input. A DC Input Multi-Axis Controller / Driver is also available to connect up to 4 axes with one unit.

AZ Series Stepper Motors with Mechanical Absolute Encoder - αSTEP

The αSTEP AZ Series stepper motors offer high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires αSTEP AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- Closed Loop Performance, No Hunting or Gain Tuning

- AC or DC Input Types

- Parallel Shaft and Right Angle Geared Types for Higher Torque, Space Savings

- Electromagnetic Brake Type Available

- αSTEP AZ Series Stepper Motor Driver Required*

αSTEP AZ Series Closed Loop Absolute Stepper Motor Drivers

The αSTEP AZD Stepper Motor Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD Stepper Motor Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), Compact, EtherNet/IP™, EtherCAT, PROFINET Compatible Types

- Multi-Axis* EtherCAT Controllers available (DC Input only)

- AC or DC Input

- For use with αSTEP AZ Series Stepper Motors, Linear and Rotary Actuators

![]()

αSTEP EZS Closed Loop AZ Series Absolute Encoder Electric Linear Slides / Linear Actuators

Compact, high-rigidity electric linear slides featuring αSTEP AZ Series with absolute encoder stepper motor and driver combined with a simple, dust-resistant structure providing the high response, low vibration and hunting-free operation of a stepper motor in an electric linear slide. A wide variety of options to suit the equipment space and environment, including straight type and reversed motor type. Being compact and rigid, this series is effective in supporting large transportable mass.

- Equipped with battery-free absolute encoder

- Positioning information can be known without a sensor

- High reliability using closed loop control

- Reduced motor heat and reduced energy consumption through high efficiency design

- Requires AZ Series Driver (sold separately)

αSTEP EAC Closed Loop AZ Series Absolute Encoder Electric Linear Cylinders / Linear Actuators

The αSTEP EAC Series electric linear actuators featuring AZ Series with absolute encoder stepper motor and driver are quick and responsive and incorporate a ball screw design, offering high performance from low speed to high speed or with light loads or heavy loads, regardless of demanding operating conditions. Available in a straight type or reversed motor type and with a shaft guide and cover version also available, saves design time and parts. All EAC Series are available with an electromechanical brake ideal for vertical operations.

- Equipped with battery-free absolute encoder

- Positioning information can be known without a sensor

- High reliability using closed loop control

- Reduced motor heat and reduced energy consumption through high efficiency design

- Requires AZ Series Driver (sold separately)

αSTEP DR/DRS2 Series Closed Loop AZ Series Stepper Motor Absolute Encoder Compact Electric Cylinders

The DR/DRS2 Series compact linear cylinder uses the αSTEP AZ Series stepper motor and driver. The actuator is equipped with the Mechanical Absolute Encoder Stepper Motor. The Absolute Encoder is a mechanical multi-turn Absolute Sensor, so an external sensor is not required. This helps to save space and reduce wiring, as well as more compact and lightweight design of the equipment.

- AZ Series Absolute Encoder Stepper Motor

- Table Type or Rod Type

- 24/48 VDC Input

- AZ Series Connection Cables and DC Input Driver required (sold separately)*

αSTEP Electric Grippers / Robotic Grippers- AZ Series Equipped

A rack-and-pinion mechanism equipped with an αSTEP AZ Series motor combined with an EH Series electric gripper. Its delicate grip, like that of a human hand, assists in automation and labor-saving.

- Provides Delicate, Human-like Grip for Robotic Applications

- 2-Finger or 3-Finger Types

- Built-In battery-free absolute sensor, for constant monitoring of motor position information without an external sensor

- High reliability with closed loop control

- High efficiency technology reduces motor heat generation and saves energy

- AZ Series Driver (DC Input) required*

αSTEP Rack and Pinion System L Series - Position Control - AZ Series Equipped

The Rack and Pinion System L Series- αSTEP AZ Series Equipped is a linear actuator in which a rack and pinion mechanism with a motor have been combined. The motor is equipped with the AZ Series that utilizes a battery-free absolute sensor, which allows for high positioning accuracy and high load transportation.

- Horizontal or Vertical movement

- High-Speed or High-Transportable-Mass Type

- Electromagnetic Brake options

- AZ Series Driver required*

αSTEP Linear Head Rack and Pinion System LJ Series - Position Control - AZ Series Compatible

When the LJ linear head with rack and pinion mechanism is attached to a parallel shaft gearhead and motor, linear motion such as pushing, pulling, raising and lowering is possible. Perfect for high load or long stroke applications. Use with the AZ Series that utilizes a battery-free absolute sensor, which allows for high positioning accuracy and high load transportation.

- Horizontal or Vertical movement

- 200 kg Mass Transportable Mass

- Electromagnetic Brake options

- AZ Series Driver required*

αSTEP Closed Loop AZ Series Absolute Encoder Hollow Rotary Actuators

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an αSTEP absolute encoder AZ series closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

- Integrated actuator and stepper motor makes design easier

- Vertical or Horizontal Mount Motor Types

- Easy Home Setting and Return-to-Home without need for sensors

- Large-diameter hollow output table

- AC or DC Input

αSTEP Hybrid Control Systems

αSTEP products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

The position of the motor is always monitored, and then the driver automatically switches between 2 types of control depending on the situation.

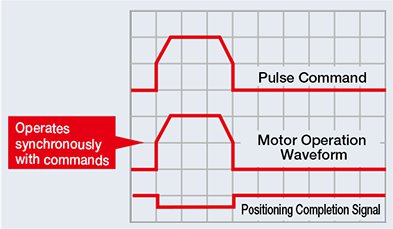

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

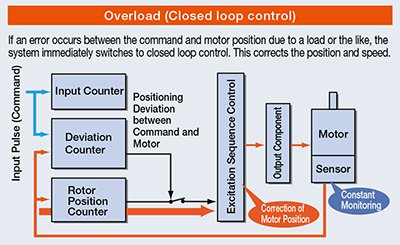

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.

αSTEP Performance

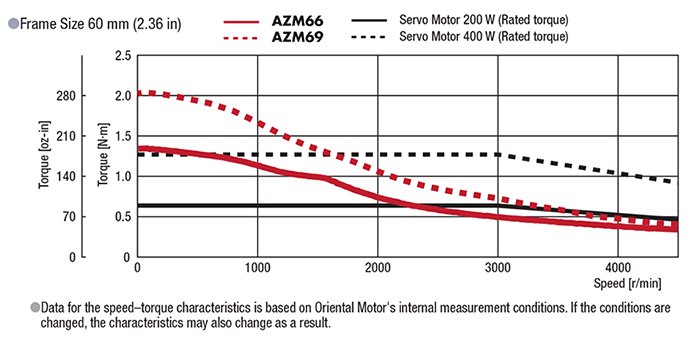

What is the Output of αSTEP?

"Rated Output" is not listed because αSTEP has no "rated speed". Refer to the graph below to compare rate torque of the αSTEP to Watts of of servo motor's rated output torque.

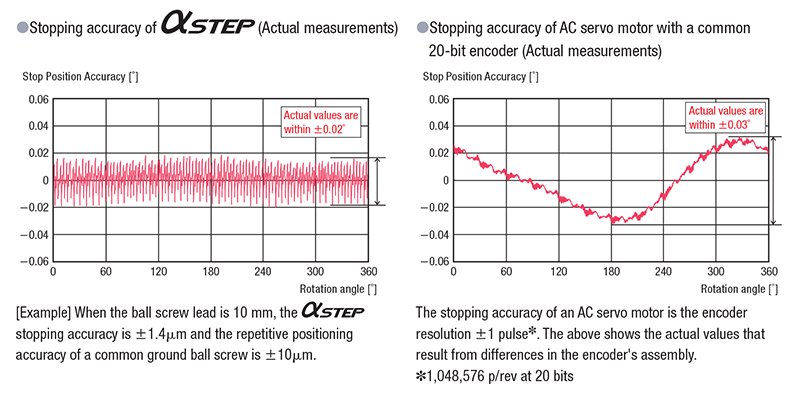

What is the Stopping Accuracy of αSTEP?

The stopping accuracy of a typical αSTEP is ±0.05° (under no load), which is equivalent to that of servo motors. The graphs below show the actual measured stopping accuracies when an αSTEP and an AC servo motor were rotated once.

Hybrid Control System

The hybrid control system constantly monitors the motors position allowing for the benefits of performance from "open loop" control while providing the assurance of "closed loop " performance.

AZ Series Drivers

AZ Series AC Input Drivers

The αSTEP AZD (AC Input) Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Available in 5 types; EtherNet/IP™ compatible, EtherCAT compatible, a stored data (network) driver, pulse input driver or pulse input with RS-485 communications for monitoring. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Driver Types:

- Pulse Input

- Pulse Input with RS-485 Communications

- Built-in Controller (Network)

- EtherCAT Types

- EtherNet/IP™ Types

- PROFINET Types

- Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with αSTEP AZ Series Motors (AC Input)

![]()

AZ Series DC Input Drivers

The αSTEP AZD-K Drivers offer 24/48 VDC input voltage, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Available in 5 types; EtherNet/IP™ compatible, EtherCAT compatible,a stored data (network) driver, pulse input driver or pulse input with RS-485 communications for monitoring. Advanced operation and function control is included through our MEXE02 software (free download). The AZD-K (DC Input) can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Driver Types:

- Pulse Input

- Pulse Input with RS-485 Communications

- Built-in Controller (Network)

- EtherCAT Types

- EtherNet/IP™ Types

- PROFINET Types

- Single or Multi-Axis

- 24/48 VDC

- For use with αSTEP AZ Series Motors (DC Input)

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.